(When it comes to shipping large amounts of goods or supplies, you’re going to need a pallet. The average pallet size in the U.S. is 48 inches by 40 inches. This is the standard size most commonly used among manufacturers, warehouses, and retailers nationwide.

More than 1.8 billion pallets exist, and only 1 billion of them are being used. Approximately 500 million new pallets are manufactured each year in the U.S. Out of them, 190 million pallets are thrown away, 150 million are refurbished for reuse, and only 25 million are recycled.

If you intend to use them for storage or shipping, it helps to know what sizes are out there, how they’re built, what loads they can support, and how the right pallet will save you time and money.

Why Do Common Pallet Dimensions Matter?

Having standard pallet sizes makes it easier on all aspects of the supply chain. Using the same pallet size makes it easier to load, stack, and store without wasting space. Forklifts and pallet jacks will be able to get them where they need to go with less fuss and more speed.

If you are purchasing new or used pallets, knowing the standard size helps you prepare for storage, minimize shipping costs, and avoid shipment holds due to incorrectly sized or oversized pallets.

The History of the Pallet

The first pallet came into the world at the dawn of the Industrial Revolution when emerging industries were looking to ship products and supplies more efficiently. Companies started using wooden planks to safely store and ship large quantities of goods using the newly invented lift truck that started popping up around the turn of the 20th Century. This spared workers from having to lift and carry products by hand. The invention of the lift truck shaped the final design of the pallet as we’ve come to know it today. The forks of the truck fit into the sleeves of the pallet, so the vehicle can support the load from both sides.

Before the trusted pallet came along, companies and workers were used to carrying large quantities of goods on wooden carts and slabs of rock. This wasn’t exactly efficient by today’s standards.

The invention of the pallet may not get as much attention as the telephone or the lightbulb, but it slowly transformed the commercial world. All workers needed was a hammer, wood, and some nails, making the pallet extremely easy and inexpensive to produce.

Shop for New and Used Stack Racks

The Evolution of the Pallet

Not much has changed in the way of pallets since they were first invented over a century ago, but there are a few key differences to note. Companies and manufacturers started looking for ways to improve the pallet as it became the gold standard in the shipping industry. Pallets can now be made using a range of materials, including wood, high-density plastic, aluminum, and steel. Metal and plastic pallets are more durable and can hold more weight than wooden pallets.

Wood can also spread dirt, germs, and debris as well as wood-borne pests like termites. Most wood pallets are now either heat treated or sprayed with special chemicals to make sure they don’t contain pests. However, wood chips and debris can still spread in the facility.

Wood pallets also proved limiting for the food industry. They can easily warp when exposed to moisture. Changing temperatures can also cause the wood to contract or expand. Grocers and cold storage companies eventually switched from wood to plastic pallets for sanitary and storage purposes.

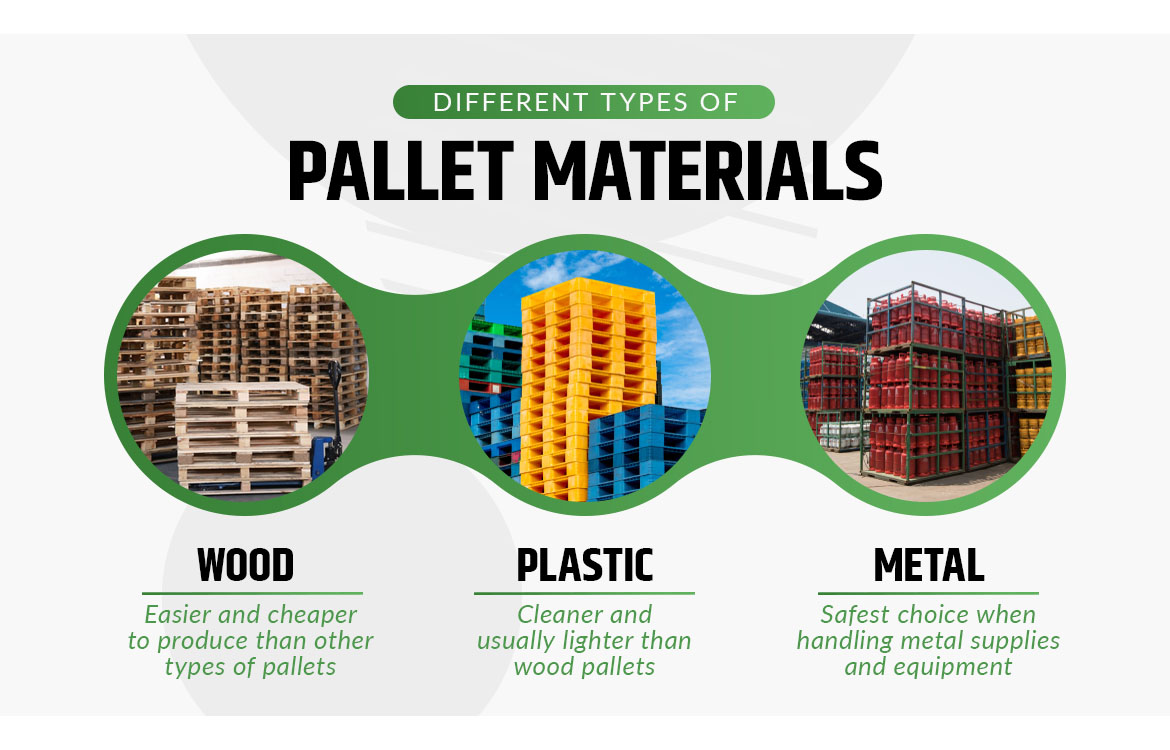

Different Types of Pallet Materials

Companies now have plenty of options to choose from when selecting their pallets. Learn more about the different kinds of pallets and how they’re used today.

Wood

Wood remains the most common pallet material, accounting for more than 90 percent of the inventory and applications worldwide. It is also the only pallet material that is 100% recyclable. Other types of pallets rely on fossil fuels like oil and gas that pollute the environment and contribute to climate change.

Wood grows naturally, which means manufacturers don’t have to use fossil fuels to create pallets. However, wood pallets can eat away at the Earth’s tree supply. In fact, wood pallets make up the largest use of hardwood lumber produced in the U.S.

There are several benefits to using wood pallets, or they wouldn’t dominate the industry. They are much easier and cheaper to produce than other types of pallets, which helps keep the initial cost of shipping low. However, they will degrade naturally over time.

Plastic

Even though fossil fuels are often used to make plastic pallets, they tend to last the test of time, so companies don’t have to keep replenishing their shipping supplies. Plastic pallets are much cleaner and usually lighter than wood pallets, which can help you save money on shipping.

There are several different ways to manufacture plastic pallets, including extrusion, thermoforming, blow molding, and injection molding, with structural foam injection molding being the most common. The manufacturer will add a foaming agent to the plastic resin during the melting process to reduce its density. Most plastic pallets are made with thermoplastics like high-density polyethylene (HDPE), and the most common blowing agent is Nitrogen.

Plastic pallets come in a range of sizes and styles. You can have the company customize your pallets by adding your logo or contact information in case it gets lost.

You can also buy used plastic pallets to save money right off the bat. These pallets won’t degrade naturally over time. Just clean it off, and it should be good to go.

Metal

A select number of pallets are made with metal, but they represent a small share of the industry. Industrial manufacturers that sell raw metal products often use metal pallets for shipping and storage. Metal beams and other sharp ends can damage plastic and wooden pallets.

Metal pallets tend to be the most expensive. They also weigh more than other types of pallets, which will cost you more over time. However, they are the safest choice when handling metal supplies and equipment. They are also incredibly durable, so you can reuse your pallet for years on end or buy used metal pallets without breaking a sweat.

Standard Pallet Sizes

|

Pallet Dimensions |

Industry Used |

|

48” x 40” |

Grocery, retail (Grocery Manufacturers Association/Consumer Brand Association standard) |

|

48” x 48” |

Chemical transport, especially plastic and metal drums |

|

44” x 44” |

Chemical transport, typically drums with hazardous materials |

|

42” x 42” |

Telecom equipment, paint canisters |

|

40” x 40” |

Cold storage, dairy products (especially milk) |

|

48” x 45” |

Automotive industry — tools, parts, and accessories |

The standard pallet size for North America is 48” x 40”, which was first established by the Grocery Manufacturers of America (GMA), who later changed its name to the Consumer Brand Association (CBA). This standard endures today as most pallets have these dimensions, with each wood board 3 ½” wide by 5/16″ thick. This standard applies to plastic and metal pallets as well.

There are other sizes to choose from, including the 42” x 42” pallet and the 48” x 48” pallet, among others. Let’s look at how each of these is used in the industry today.

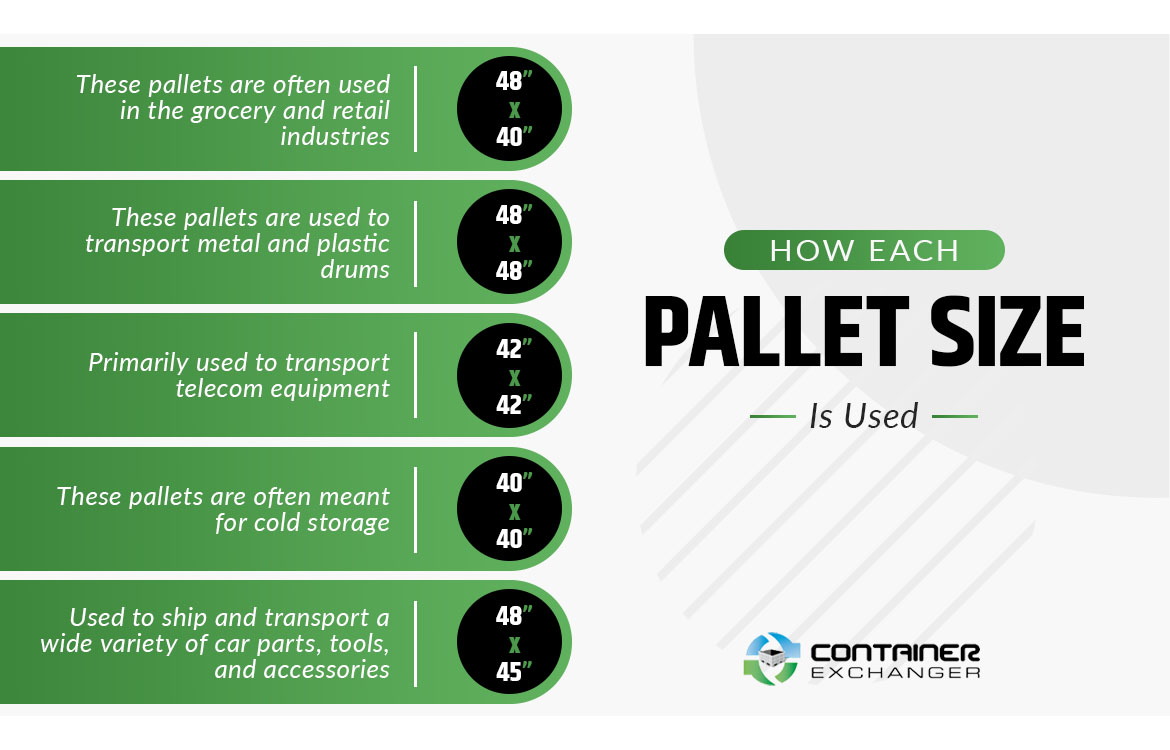

48” x 40”

Around 35% of all pallets in circulation worldwide are 48” x 40”. These pallets are often used in the grocery and retail industries. This is often referred to as the GMA standard.

48” x 48” and 44” x 44”

While rare, these pallets are often used to transport metal and plastic drums, which often contain hazardous chemicals.

42” x 42”

These pallets are primarily used to transport telecom equipment and dozens of canisters of pain.

40” x 40”

These pallets are often meant for cold storage and are used to ship and store dairy products, most often milk.

48” x 45”

These pallets remain the preferred choice in the automotive industry. They are used to ship and transport a wide variety of car parts, tools, and accessories.

Factors to Consider When Choosing the Right Pallet Size

Selecting a pallet for your business is not a simple case of one-size-fits-all. If there is a standard size for your industry, it’s smart to match the type and size your suppliers or partners use. Establishing an industry standard keeps the supply chain moving as fast as possible.

If you are shipping internationally, your wooden pallets must be treated. Otherwise, you’ll need to use plastic or metal pallets to pass inspection at customs. International regulations require inspection of all wood packaging materials before entering a country.

Think about how long you expect to use the pallet. If you want to keep your pallets in rotation for years at a time or there’s a chance they may be exposed to moisture, you’re much better off opting for plastic or metal pallets.

However, if you’re looking to save as much money as possible and don’t plan on using the pallet for very long, wood will be your best option.

It’s usually best to match your materials when choosing a pallet for a specific type of container. For example, pair plastic totes and containers with plastic pallets to avoid damaging your shipping materials.

Find Used Commercial Racking Systems Online

Product Dimensions and Weight

Pallet size should match both the shape and weight of your product. Larger or irregularly shaped items may need custom pallets for proper support. Heavy items often require block pallets or a solid deck pallet to prevent collapse. Selecting the right size and type helps reduce product damage, avoid shifting during transport, and ensure safe stacking in storage.

Available Storage Space

The space available in your warehouse or trailer plays a major role in choosing pallet size. If you’re working with limited floor space or tight racking, square pallets or smaller pallets can help fit more units efficiently. Four-way pallets also improve maneuverability, making it easier to access inventory in narrow aisles or multi-level storage areas with minimal repositioning.

Pallet Shipments

If you’re shipping large quantities, you’ll need to consider how many pallets are shipped together and how they’re arranged. Using standard-sized pallets helps reduce wasted space in trucks and shipping containers. When moving specialized items like packaged paper, bulk liquids, or drums, you may need specialized pallets designed to maintain stability and prevent shifting while in motion.

Loading and Unloading Equipment

Not every pallet works with every piece of equipment. Stringer pallets and GMA pallets are compatible with most forklifts and pallet jacks. However, Euro pallets and CP pallets may require different fork spacing or loading angles. Choosing pallets that match your equipment reduces loading time, prevents mishandling, lowers labor costs, and keeps your workflow moving consistently.

Industry and Regulatory Standards

Your pallet choice may be influenced by compliance requirements tied to your industry. GMA pallets are widely accepted in the food and retail sectors. The European Pallet Association enforces strict pallet standards overseas. If you’re shipping chemicals or crossing international borders, your pallets may need to be treated, certified, or even made of plastic or metal to meet regulations.

Storing Pallets on the Rack

You will also need to find a way to store and organize your pallets on the shelf. Many warehouses and industries use stack racks to create aisles for their products and supplies. Each rack may contain a certain number of shelves based on the height of the container. Your team can then use lift trucks to quickly retrieve pallets from the shelf. Traditional stack racks are the best choice when using a first-in last-out storage system. The first pallet to go on the rack will be the last pallet to go out.

You can also stack your pallets directly on top of each other, but the stack will become unstable after three or more rows. You also won’t be able to reach the pallet on the bottom until all the pallets have been taken away.

If you want to keep your pallets moving or plan on using the first-in first-out storage method, you can use pallet flow racks where the load is moved from one end of the rack on a conveyor that allows the pallets to be removed in a FIFO manner.

You can also use driving in racking systems to let drivers bring pallets into the racking system or push back racks that automatically spring loads forward when a pallet is taken away. These types of stack racks are used in last-in first-out retrieval systems.

You also need to consider how you plan on placing the pallet on the rack. Many facilities use wire decking for pallet racks, which creates a smooth surface from one end of the shelf to the next. This is much more stable than placing the pallet directly on the beams of the rack. If the load is unbalanced or not seated properly on the rack, it could easily fall over.

Pallet Packing and Handling Tips

Practice proper loading techniques when stacking containers and loose items on your pallets. Pay attention to the weight capacity and weigh your goods beforehand to make sure they stay within the requirements.

Remember to distribute the weight as evenly as possible to prevent the load from tipping to one side. Make sure you don’t stack your containers too high so that they block the driver’s line of sight when they are moving the pallets. Consider utilizing reusable bulk storage containers that are designed to fit onto a pallet. This simplifies the loading process. You can then use ratchet straps to secure the cargo to the pallet instead of shrink-wrapping multiple packages and boxes together.

If you plan on reusing your pallets, you can track them as they make their way through the supply chain using an automated warehouse system. Attack remote trackers to your shipping supplies to make sure they come back in one piece.

With a little bit of research and planning, you can find the right type of pallet for your industry.

Final Thoughts on Pallet Sizes and Selection

There’s no perfect pallet for every situation. The best size depends on what you’re storing, how you’re moving it, and where it’s going. Standard pallet dimensions help with smoother pallet shipments, but there’s room to adjust based on your setup. New wood pallets, plastic, and custom builds each serve different purposes, so it’s worth choosing carefully.

Need pallets that fit your operation? Shop new and used options today at Container Exchanger for better pricing, faster turnaround, and pallets built to perform.

FAQ

How much weight can a standard pallet hold?

A standard pallet with 48x40-inch dimensions can usually hold between 2,000 and 4,600 pounds, depending on how the load is distributed. Load capacity also depends on whether the pallet is being stored, moved, or racked. For efficient handling, avoid exceeding the recommended load weight listed by the manufacturer.

How much does shipping a pallet cost?

Shipping costs depend on pallet weight, size, distance, and whether you’re shipping domestically or dealing with international shipping regulations. Heavier loads and oversized pallets may cost more. Standardized dimensions help keep costs lower by maximizing space in freight trucks and minimizing delays during pallet shipments across global supply chains today.