Source: Dizfoto/Shutterstock.com

Steel is one of the world’s most dependable materials. It’s used in all kinds of industries, including many of the products we use every day. These products are made using a process known as steel fabrication. It’s when a skilled technician or craftsperson transforms raw steel into a part or product with specific dimensions. The steel fabrication industry is booming and is expected to be worth $21.38 billion by 2024.

If your company is looking to fabricate steel, here’s what you need to know:

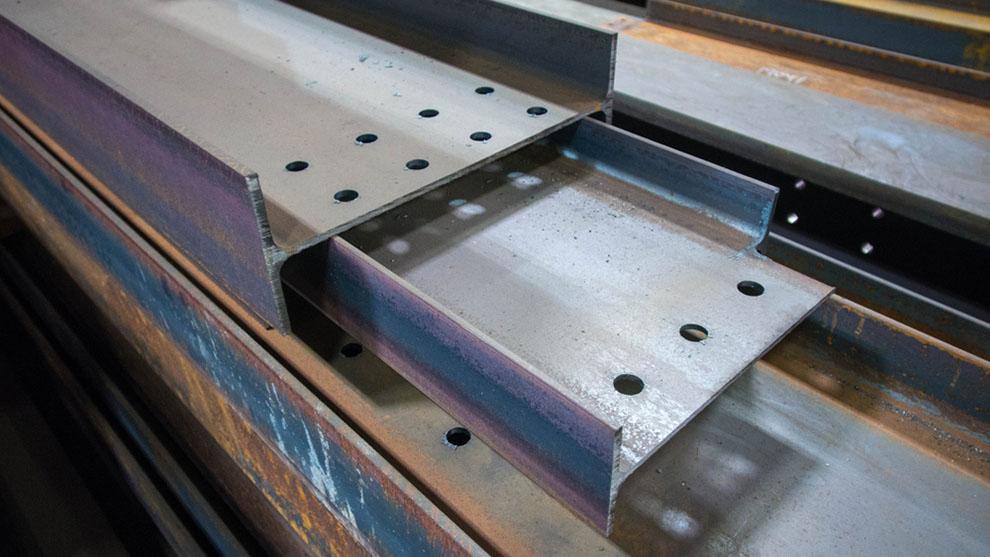

The Steel Fabrication Process

Don’t be shy if you don’t know what steel fabrication is. It’s a complex process requiring months of training and experience. There are several different ways to turn raw steel into specific parts and products. Many of these processes can be automated as well.

- Machining is when the technician uses a specialized drill or sander to shave away the metal. This is usually the best way to get a smooth curve or round edge.

- Cutting is when the fabricator uses highly pressured water to jet cut the steel into a specific shape. It produces fine edges and lines, perfect for exact measurements.

- Welding is used to combine multiple pieces of steel into a single product. It’s perfect for making right angles, joints and other complex parts and machines.

Many companies are also using CAD or 3-D printing to automate the steel manufacturing process. This is when the designer builds a model or template of the part or product on the computer. The printer will then generate the design automatically using raw steel. This gives the fabricator more control over the finished product.

Order Your Pallet Container Today!

Source: Rachid Jalayanadeja/Shutterstock.com

How to Get Started in Steel Fabrication

To be a successful steel fabricator, you need to know your market. You will have to come up with a product or design that can be sold to companies, retailers or consumers. You can also contract directly with companies that use steel to see if you can outbid their competitors.

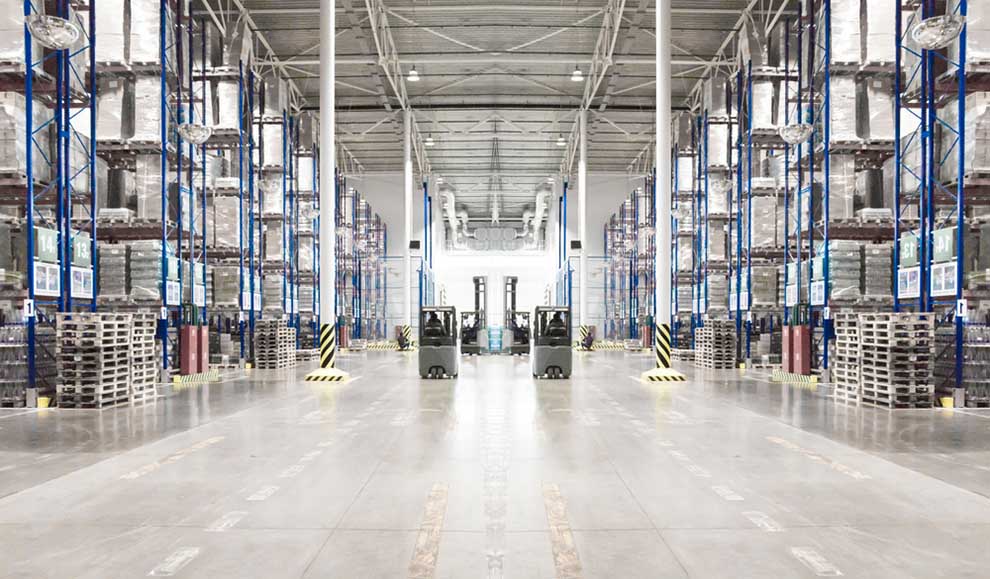

You will also need a facility to bring these products or parts to life, such as a garage or warehouse facility. Invest in the following supplies and equipment to get your operation off the ground:

Raw Steel: You will need to stock up on raw steel. Look for local suppliers to reduce the cost of shipping, as steel can be quite expensive to transport. Raw steel comes in several sizes and shapes, including steel plates, flat sheets, sectional “L” beams, bars and tubes. Choose a style that works for your business.

Fittings and Castings: Use these templates or models to forge your steel into unique shapes and designs. You can then weld individual parts together to make the finished product.

Welder and Welding Wire: The wire is often used to hold the pieces of steel together as they are welded together.

Cutting Equipment: Use a high-pressure jet water system to cut up the steel into smaller parts.

Sander or Drill: Use it to create a smooth surface that will please your customers and clients.

Polisher: Consider adding a polish to improve the look of your products.

Pallet Container: Use a metal pallet container to ship your products to your clients. Find a way to package the container to minimize empty space. Consider having your clients or customers assemble your products when they arrive so you can fit the individual parts into the same container.

Need More Space? Use Collapsible Plastic Box Pallets

Metal Pallets: It’s best to use metal pallets to ship your products. Steel can weigh down wood pallets, causing them to break or snap in two. Aluminum pallets are a cheaper, lighter alternative to steel. Learn more about the differences between galvanized steel vs. aluminum pallets. You can also use collapsible plastic box pallets to save on shipping.

Source: Studio Dagdagaz/Shutterstock.com

Getting into the steel fabrication business may not be as hard as you might think. The world is moving away from disposable materials like plastic, wood and paper. More companies are using steel to create lasting products that will stand the test of time.

Find a way to make your mark on the steel fabrication industry by coming up with a product or part that will please a variety of customers and clients. Use high-quality metal manufacturing and shipping materials to keep your products safe every step of the way.