If your crew is moving totes all day, the numbers on the data sheet translate directly into safety, uptime, and damaged product risk. Forklifts, racks, and trailers all have limits, and a bad estimate shows up fast in bent steel or spilled liquid. Breaking IBC tote, also known as IBC tanks, weight into clear numbers helps your team plan handling, racking, and shipping with fewer surprises.

Introduction

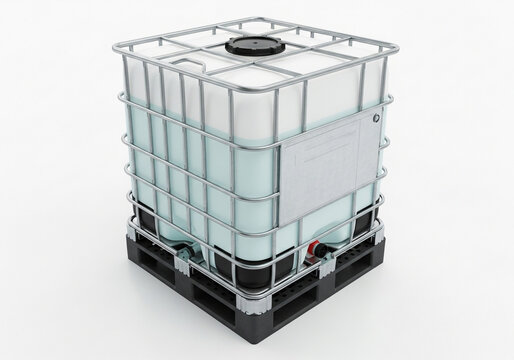

Before we get into the nitty gritty of containers, let’s get into the basics: what is an IBC tote? An IBC tote, also known as IBC tank, is a square, stackable tank in a metal cage on a pallet base, built so forklifts can move a lot of liquid at once and so your team can keep weight under control in the warehouse.

How Much Does an IBC Tote Weigh? (By Capacity)

Once you look at tote weight by capacity, the numbers get easier to use. You can line up empty and full weights with your racks, floors, and forklifts instead of guessing what a full tote might mean in day to day operations.

A quick reference for standard IBC tote weights looks like this:

| Capacity | Empty Weight (Approx) | Full Weight With Water (Approx) | Notes |

| 275 gal | 120–160 lbs | 2,300–2,500 lbs | Most common size |

| 330 gal | 140–200 lbs | 2,900–3,100 lbs | Taller, more capacity |

| 350 gal | 150–220 lbs | 2,900–3,200 lbs | Higher volume specialty |

| 550 gal | 200–300 lbs | 4,500–4,800 lbs | Very heavy floor loads |

Use this chart with your racking specs and IBC totes height, width, and length base dimensions so every location matches a safe working load.

275 Gallon IBC Tote Weight

A standard 275 gallon tote sits in the sweet spot for many warehouses. Empty weight usually falls between 120 and 160 pounds, depending on pallet material and design.

- Plastic pallet bases keep weight lower.

- Steel pallet bases add strength and durability but add a bit more empty weight.

Filled with water, the total weight climbs to roughly 2,300–2,500 pounds. Once you move into heavier liquids, like some chemicals in the industrial market, total load can rise fast, so it pays to check the specific gravity rating before you assign rack locations or trailer spots.

330 Gallon IBC Tote Weight

A 330 gallon tote pushes capacity up without changing the footprint much, which is one reason it shows up so often in large operations.

Empty weight usually lands between 140 and 200 pounds. That extra liquid volume, combined with a taller cage and heavier pallet, drives both the tare and the full weight higher than the 275.

With water, a full 330 gallon tote often comes in around 2,900–3,100 pounds. Many of these IBC containers are rated for dense materials, so always confirm the label and make sure the rating suits your heaviest product.

350 and 550 Gallon IBC Tote Weights

Larger sizes like 350 and 550 gallon units show up in high volume applications where each move needs to carry as much as possible.

Empty 350 gallon units sit above the 330 range because of the taller bottle and cage, and 550 gallon units can push well over 3,500 pounds full with water. Those loads usually call for heavier duty handling gear and ground level storage, with layouts planned around the fact that these intermediate bulk containers put serious weight into every spot they occupy.

Factors That Affect IBC Tote Weight

Capacity is only part of the story. IBC totes dimensions, design, materials, and fittings can shift empty weight enough to matter for racking, stacking, and shipping plans, so it helps to know what is adding pounds in the background.

Pallet Base and Cage

The pallet base is a major driver of empty weight and handling. Plastic bases are lighter and resist moisture and rust, wood bases can be affordable but need more care, and carbon steel bases add strength and impact resistance along with extra pounds. The steel cage also matters, since rod thickness, cross bracing, and UN rating change both weight and durability, with heavier cages usually holding up better to rough handling around docks and shipping areas.

Bottle and Fittings

Most modern bottles are made from hdpe, a form of high-density polyethylene. Wall thickness, resin type, and whether the unit is food grade or industrial grade all shift the tare weight and the way the tote handles aggressive chemicals or demanding applications.

Valves, caps, and fittings also add a small but real amount of weight. Larger outlet valves, specialty connections, and reinforced fittings can add a few pounds per unit, which starts to matter when you are lining up stacked totes on racks or in trailers close to their rated limits.

Safety Guidelines for Handling Heavy IBC Tanks

Totes feel manageable on paper, yet once you pass the 2,000 pound mark, mistakes can get expensive fast.

- Confirm forklift capacity before assigning tasks. Take into account the load center, not just the headline rating.

- Keep forks fully under the pallet base, with even spacing and slow travel when you are transporting liquids.

- Check rack beams, supports, and anchors to ensure they match the tote weight plus a safety margin.

Training around real weight numbers helps operators understand why speed and shortcuts are not worth the risk.

Shop IBC Totes With Confidence

Once you know the empty and full weights that fit your racks, floors, and forklifts, it is much easier to choose the right totes for your operation. Matching capacity, dimensions, and ratings to your products and workflows keeps crews safer, reduces damage, and helps every move stay predictable. When you are ready to source used or new IBC totes for sale that line up with your weight requirements, Container Exchanger can connect you with options that are already proven in the field.