The differences between galvanized steel and aluminum metal pallets concern the differences in the properties of the metals used. Which material you use for your business needs depends on a number of different factors, including what you ship.

Below, we have laid out the pros and cons of each so you can make an informed decision before committing to one or the other.

Galvanized steel

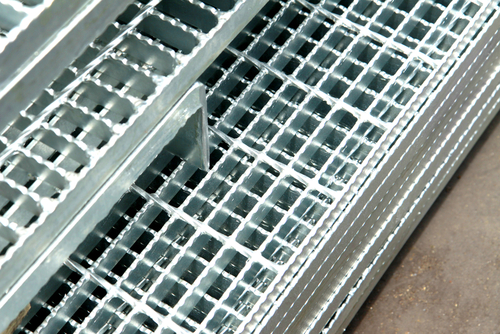

The Italian Luigi Galvani invented the process of making galvanized steel; hence, the name. Galvanized steel is made by dipping carbon steel in molten zinc, using electricity. The molten zinc clings to the surface of the steel, creating a thin durable film that will not peel or flake. This film protects the metal against corrosion. This galvanization process provides advantages for shippers.

Pros and Cons of Galvanized Steel Pallets

Galvanized steel is extremely tough and dense. Because of its strength, you do not need to use as much, so the weight becomes less of a factor. Due to the weight, though, many find it more difficult to assemble, but, once it is in place, you can be confident it will stay put.

Its strength is, undoubtedly, its most significant advantage, allowing it to handle a great deal of weight and heavy forklift usage.

Compared with aluminum, galvanized steel over time is a much more cost-effective solution. Galvanized steel requires less maintenance than aluminum. Since the galvanization process inhibits rust, this is a much better material to use in humid conditions. You won’t need to compromise on the durability of your shelving units. UV rays, rain, and snow affect it much less than these conditions affect aluminum.

Benefits of Galvanized Steel Pallets for Transport Companies

- Extremely durable

- Good return on investment

- Great for outdoor storage

- Fire resistant

Aluminum

Aluminum has a low density, which results in a higher heat exchange compared to galvanized steel. Its low density makes it a better thermal conductor, giving it better heating and cooling properties than steel. Because of its light weight, it usually is cheaper to buy than galvanized steel, but it is not as durable in the long term. Aluminum also resists corrosion, but not quite to the same extent as galvanized steel.

Its corrosion resistance comes from the formation of aluminum oxide, created when the raw aluminum reacts with the atmospheric oxygen and produces a thin layer of aluminum oxide.

Pros and Cons of Aluminum Pallets

For food storage and distribution centers, aluminum is preferred because of its smooth surface. The smooth surface provides better antibacterial properties. A smooth surface does not have crevices that make it easier for bacteria to thrive. Aluminum is easier to clean and sanitize, whereas galvanized steel can be rough and porous and cause bacterial growth.

Aluminum won’t give or bend as much as steel, so, in the event of overloading or high-energy impact, aluminum is susceptible to breaking.

Aluminum also doesn’t absorb vibrations as well as steel, which can sometimes be a liability.

Benefits of Aluminum Pallets for Transport Companies

- They have a high load capacity

- They are suitable for an R-beam system

- They are fully recyclable

- 100% aluminum pallets are very easy to clean

- They are less vulnerable to pest infestations and vermin

- Their lighter weight reduces shipping costs

Conclusion

Choosing between aluminum or steel depends on whether cost or weight is a more significant concern for business. Aluminum pallets have a high price tag but are preferred for their lightweight yet strong design, which can help in cutting transportation costs. This lower cost can impact the final price passed on to customers, as it allows for cheaper and rapid delivery if shipping by air. While not as resistant to corrosion as galvanized steel aluminum metal pallets, it will still hold up well compared to most other materials.

Businesses that require strength and durability, and which need not worry about airfreight costs, will get more value out of galvanized steel. Because it has been galvanized, it can hold up against almost any atmospheric or weather conditions, making these types of metal pallets solid long-term investments. However, if your company handles food products regularly, then you might want to consider aluminum, instead, because its smooth surface is easier to sanitize.

Galvanized steel works well when enterprises rely on heavy industrial equipment in production and distribution operations, especially in humid or wet conditions.

The differences are slight but, over time, can make a significant impact on your bottom line.