Source: Juice Flair/Shutterstock.com

Warehousing companies are looking for new ways to manage and store their goods as the industry continues to automate key aspects of the supply chain. This has led to the rise of what’s known as an automatic storage and retrieval system (AS/RS). It’s a type of warehouse where machines retrieve items from the shelves and bring them to ground level, so workers can move these items to the loading dock and send them out for delivery.

This technology is changing the game when it comes to product picking and inventory management. The COVID-19 pandemic spurred unprecedented interest in automatic storage technology. The global market for AS/RS warehouses is expected to reach $10.7 billion by 2025, and that’s just the start of what will likely be a gradual transition to fully automated warehousing.

Learn more about this technology and how it can help you achieve your goals.

What Is an AS/RS Warehouse?

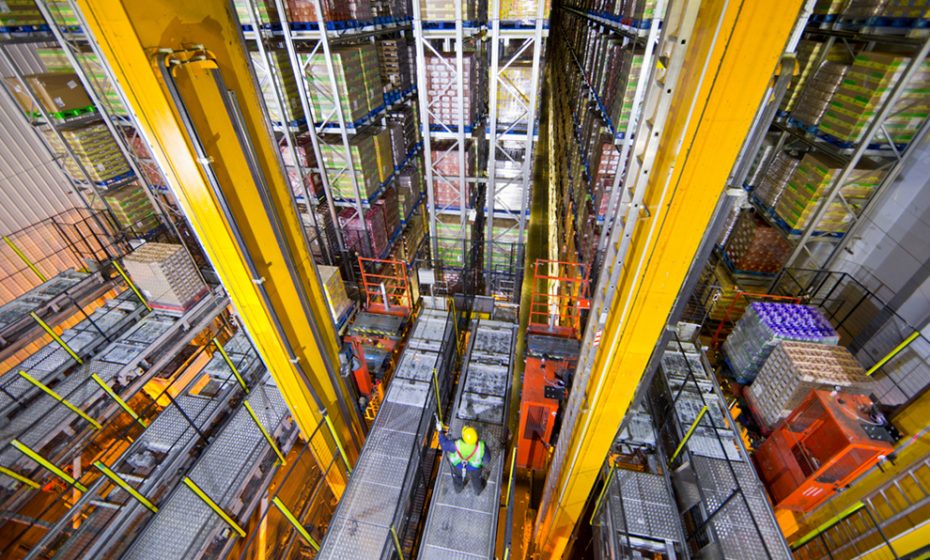

An AS/RS warehouse is a nearly fully automated warehouse where most of the goods are stored in a complex network of shelves and slots that usually expand vertically as well as horizontally. Machines, including shuttles, cranes, carousels and vertical lift modules (VLMs), move goods in and out of the system as needed. The goods are typically beyond the reach of human beings.

Source: Juice Flair/Shutterstock.com

Typically, the system will automatically pull items from the shelf as soon as the order comes in. In other cases, workers may have to use the warehouse management system to request specific goods. The system works in reverse as well. The machine will automatically restock incoming supplies and merchandise, tucking it away until it needs to go out for delivery.

AS/RS warehouses come in many forms. The system may use robotic arms or a spring-forward system to retrieve items from the shelf. It should be designed to handle different kinds of merchandise without damaging them along the way, depending on what kinds of products you sell.

You’ll Need a Collapsible Bulk Container for Your AS/RS Warehouse

What Are the Benefits of Having an Automated Storage and Retrieval System?

The main benefit of using this technology is to utilize more of your storage space. Warehouse rental rates are higher than ever before, so it makes sense to fit as many of your goods on the shelves as possible. The AS/RS model will let you stack products as high as the ceiling, in some cases, while giving your workers more room to move around. However, if the machine breaks down, your workers may be unable to retrieve these items by hand.

Automating the retrieval process also reduces the risk of workplace accidents and injuries, especially when handling heavy merchandise that weighs several tons or more. The machine does the heavy lifting while your workers focus on accuracy and coordinating delivery times. You likely won’t need as many workers with this technology in place, reducing labor costs.

The system should also improve picking accuracy. You won’t have to worry about your workers pulling the wrong item or sending out the wrong package by mistake.

Order Your Industrial Wire Baskets Today!

Source: Unique Vision/Shutterstock.com

What Does It Take to Implement an AS/RS?

Add these essentials to your budget when adopting an AS/RS warehouse:

-

Warehouse Management System

Every facility with this technology in place uses an automated warehouse management system (WMS). You will use this interface to retrieve items, monitor orders and manage your inventory.

-

IT Services

You will also need access to reliable IT services when operating this technology. You are bound to run into a few issues when bringing this technology online. Make sure you have the support you need to properly manage your inventory.

-

Visible Storage Containers

The AS/RS system makes it difficult to access your products by hand. This makes it nearly impossible to conduct regular spot checks. Use industrial wire baskets to keep your inventory visible, so your workers can see how many items are on the shelf from a distance.

-

Pallet Containers

Many automated warehouses use collapsible bulk containers to safely move items from one location to the next. It keeps the contents securely attached to the pallet for easy handling. This is also the safest way to ship your inventory. Keep your products in the same container to simplify the order fulfillment process.

AR/RS Systems Are the Future

The future is automated, so consider implementing an AS/RS system today to increase efficiency and employee safety at every turn.