When it comes to the supply chain, companies tend to overlook a crucial component of their business: reverse logistics, or the idea of the end user sending products to a new location or back to the original manufacturer or vendor. In layman’s terms, this is what we’d typically call a return. If the customer isn’t satisfied, they will send the product back for a full refund.

Reverse logistics can also refer to repairs, repackaging, product disposal, delivery errors, rentals and leases. Regardless of the nature of your business, reverse logistics should play a role. The easier it is for your customers to make a return, the more satisfied they will be with your business.

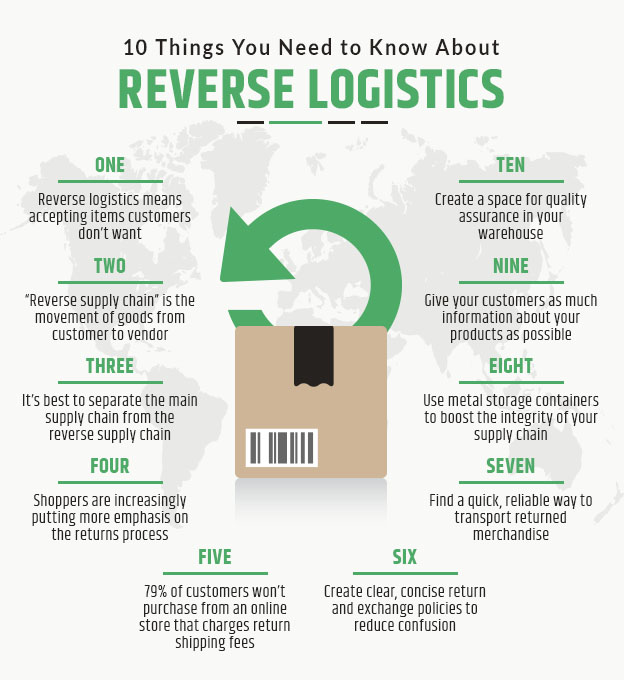

Learn more about reverse logistics and the returns process so you can better meet the needs of your customers and move products back and forth with ease.

Understanding Reverse Logistics

Returns on the Rise

Nothing could be more frustrating to a customer than not having the means to return something they purchased, especially if they did so online.

SHOP COLLAPSIBLE BULK CONTAINERS AND SAVE!

The internet and the rise of the eCommerce industry has changed reverse logistics for the better. More customers are ordering goods online than ever before, but statistics suggest they aren’t always satisfied with the things they buy online. eCommerce return rates tend to be around 20 percent, over double the rate of brick-and-mortar returns.

When ordering online, customers have to rely on product descriptions, photos, videos and customer reviews instead of examining the product in person. The product may appear or work differently in person than it did online, which contributes to the high rate of returns.

Remember the phrase, “The customer is always right”? Shoppers are increasingly putting more emphasis on the returns process. They expect retailers and vendors to take care of their returns quickly with minimal inconvenience. Customers say they should have the freedom to shop and return as they please, even if it incurs additional costs for the company.

What Is Reverse Logistics?

Reverse logistics can take many forms. It all depends on the nature of your business and how your customers respond and react to your products.

If your business sells physical consumer goods, reverse logistics often means accepting items the customer no longer wants, broken items or those that need repair. Your business will then need to replace the product or refund the customer’s money, as well as repair or dispose of the unwanted item.

If your business sells equipment and supplies to other businesses, your clients may need this equipment repaired or re-serviced from time to time. This means you have to find a way to ship the product to a certified repair technician and then back to the end user. As for industrial products, such as solvents, chemicals and detergents, you also need to establish protocols so your customers can dispose of these products properly if they need to be replaced.

When disposing of returned items, pay attention to the environment. If your product uses biodegradable packaging or has been treated to reduce pollution, disposing of these items becomes much easier and cost-efficient. Learn more about the advantages and disadvantages of green logistics.

When selling food and medicine, reverse logistics often comes down to quality assurance. If your products arrive damaged, contaminated or expired, your company will need to refund your customers and establish means for disposing of this food.

Reverse Logistics vs. Reverse Supply Chain

When reversing the flow of goods, your business needs to define how far these goods need to go back up the supply chain.

The term “reverse supply chain” refers to the movement of goods from a customer to a vendor or at least one step backward up the supply chain. You may not have to send returned products all the way back to the originating site. Some companies will send returned products to a quality control station so they can physically inspect and test the product before deciding whether to repair or dispose of it. These stations may be a part of the normal supply chain or exist within an outside system.

In some cases, the return supply chain can lead to an entirely different route, thus eschewing the traditional means of production and distribution. One set of employees handles returns and exchanges, while another set focuses on fulfilling orders so these departments do not overlap.

How to Set Up a Reverse Supply Chain

There’s a lot to keep in mind when setting up a reverse supply chain. Use these tips to make the process as smooth as possible, while keeping your customers satisfied every step of the way.

Establish a Separate Route

Generally speaking, it’s best to separate the main supply chain from the reverse supply chain so returned products and outgoing products do not encounter one another.

CHECK OUT OUR ASSORTMENT OF STACKABLE WIRE BASKETS

Create a separate system for picking up and redistributing returns to avoid putting additional strain on your primary delivery team. Getting new orders out the door can be a challenge as it is, so unless you have a small warehouse facility, separate these processes as much as possible. Create designated areas for inspecting returned products and shipping out new orders to reduce confusion in the workplace. Using the same supply chain for returns and deliveries can lead to bottlenecks as drivers try to juggle multiple routes at the same time.

With a separate system, you don’t have to worry about the number of returns overwhelming your delivery and distribution operations.

Don’t Charge for Shipping

The statistics are clear: 79 percent of customers won’t purchase from an online store that charges return shipping fees. If you charge your customers for return shipping, they will feel like they are being punished for something they didn’t do. It is your responsibility to make sure your customers are satisfied with your products.

When a customer orders a product from your website, you need to plan for the possibility of a return.

Make It Easy

Even if your customer changes their mind, returning these items shouldn’t be a chore.

Make it easy for your customers to return items. You can use UPS, FedEx or the U.S. Post Office as long as you pay for shipping and provide the required postage and packaging.

Consider creating your own fleet of drivers for handling returns. They can drive right to the customer’s door, handle the return and move on to the next claim. This gives your team the chance to repair or refurbish equipment in the customer’s home, if possible, instead of shipping back to headquarters.

You can also partner with local businesses to create a network of customer “return stations” so shoppers can easily drop off unwanted items in their neighborhood. Drivers can then collect these returns on a schedule that works for your business instead of going from door to door.

Establish Clear Return Protocols

When returning an item, your customers need information. Create clear, concise return and exchange policies to reduce confusion. Your customers should be able to find this info without going out of their way. You can include this information on your website, inside the shipment container or via email.

Establish who’s eligible for a return and why, as well as a concrete return timeline or window. Are there any exceptions to these rules? Ask yourself whether these terms and conditions seem fair. Make sure you are working in the best interest of your customers as opposed to boosting profits. Include specific instructions for returning these items.

Transporting and Collecting Returns

Depending on the nature of your products, you need to find a quick, reliable way to transport returned merchandise. Some items may no longer be in their original packaging, while others may need urgent repairs. On the other hand, you may not need to secure these items during transit if you plan on disposing of them.

Use collapsible bulk containers when collecting and picking up returns. They have lots of room for all kinds of merchandise so drivers can quickly grab and store a range of miscellaneous items. Drivers can also collapse these containers when they are not in use, helping them manage the flow of goods on the road. If they are doing returns and drop-offs in the same trip, they can reuse these containers as cargo volumes fluctuate throughout the day.

These containers also come in handy in the warehouse. You can easily stack them on top of each other and get them out of the way when they are not in use. Keep one stack for returns and another for incoming/outgoing merchandise.

Stackable wire baskets are great for sorting and distributing returned items. Once you’ve gone through these items, your team can use baskets to quickly put them back on the shelf. These containers keep your merchandise visible so you don’t have to open them to see what’s inside. Workers can quickly reach inside the container, find what they need and get back to business.

Reducing and Preventing Returns

If you don’t like dealing with returns, join the club. Processing returns can be expensive and time-consuming. There are lots of things you can do to reduce the rate of returns.

Proper Shipping

Mishandling your products will almost certainly lead to a spike in returns. The product may appear usable when you send it off for delivery, but it could arrive damaged if you don’t use the proper container.

Use metal storage containers to boost the integrity of your supply chain. They are considered much more durable than cardboard boxes. You won’t have to worry as much about water, turbulence and other hazards ruining the quality of your products.

Use Clear Product Descriptions

Try to give your customers as much information about your products as possible before they click the “Buy Now” button. Use high-quality photos and videos to show them how the product looks and feels in person. Include customer reviews to create a more informed shopping experience.

Write these descriptions with the end user in mind. Think about what these shoppers are looking for in a product and how they will incorporate it into their lives. The more accurate and helpful you make your descriptions, the less likely your customers will be to request a refund.

Invest in Quality Assurance

We all know how hectic getting orders out the door can be in the supply chain industry, especially when time is of the essence. Your team may be more focused on product picking, printing shipping labels and wrapping packages than inspecting physical merchandise.

Create a space for quality assurance in your warehouse so that all goods must pass through this space before going out for delivery. You may need to change the fulfillment process or rearrange the layout of your facility to make this happen. You can use stack racks, conveyor belts and sorting racks to quickly hand off merchandise in the workplace.

Avoid rushing through this process, as your company’s reputation could suffer as a result. Give your workers plenty of time to assess these products. It’s best to inspect these items twice–once when they come into the facility and again when they go out for delivery. The quality and condition of your products may change over time as they stay in storage.

Create a log of returns so you can track and respond to any trends as soon as they appear. If one of your products starts causing headaches for your customers, you may need to take it off your website, issue a recall or fix some mechanical issues before shipping out new orders.

Reverse logistics can feel like an uphill climb, but it’s an essential part of the retail industry. As long as your customers keep buying your merchandise, they will continue to return it. Invest in the right containers, quality assurance and proper item descriptions to reduce the rate of returns.