Throughput is the measure of finished, quality goods a company can produce within a given period of time. Increasing your throughput will help you complete more orders, boosting your profits and helping you send the right message to your clients.

When it comes to increasing throughput, the goal is to raise this number without dramatically escalating the cost of your operations. Learn how to make the most of your existing warehouse space by improving the layout of your facility, investing in the proper storage equipment and regularly auditing your workflow.

Over time, you can increase your throughput, take on more clients and establish your facility or company as a reliable distribution center in your industry. In 2015, we saw an 18.5 percent increase in the total number of SKUs handled by the average warehouse or order fulfillment operation. These numbers are expected to increase year after year.

Don’t get left behind. Here’s what you need to do to make sure you’re getting as many orders out the door as possible.

Measuring Your Current Throughput

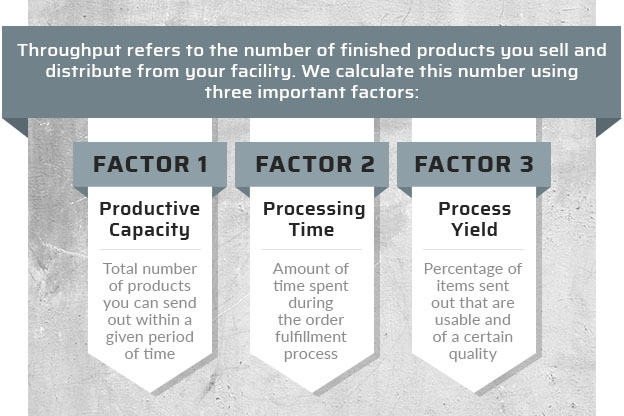

Before we talk about all the ways to increase this important metric, let’s talk about what we mean when we say throughput.

On a simple level, this term refers to the number of finished products you sell and distribute from your facility. We calculate this number using three important factors:

- Productive Capacity: the total number of products you can send out within a given period of time.

- Productive Processing Time: the amount of time spent adding value to your products during the manufacturing or order fulfillment process.

- Process Yield: the percentage of items you send out that are usable and of a certain quality. If any of your products are damaged during the manufacturing or fulfillment process, they will be deducted from your throughput.

To calculate your throughput, use the following equation:

Productive Capacity x Productive Processing Time x Process Yield = Throughput

You can’t increase your throughput unless you measure and analyze your current throughput. Use a warehouse management system to tally the total number of orders you get out the door within a day, week or month. See how these numbers change over time and identify key variables that affect the total.

Measure how much productive processing time you need to maintain a certain level of quality, so your yield stays as close to 100 percent as possible. The last thing you want to do is send out damaged or poorly constructed products to your customers.

How to Increase Throughput

Now that you understand your current throughput, it’s time to start optimizing your warehouse for higher production capacity, so you can get more products out the door. Continue to measure your throughput as you begin implementing these changes.

Group Products According to Demand

Comb through your sales data to figure out which products tend to be the most popular with your customers and when. Keep the most popular products in readily available areas, so your pickers don’t have to go out of their way to retrieve these items on a regular basis. You can even put these items in the packaging area to reduce fulfillment time.

You should also adjust the layout of your facility if the most in-demand products tend to change from season to season. For instance, keeping your winter items in the packaging area doesn’t make a lot of sense if it’s the middle of June. Analyze your customer buying habits to make sure the most in-demand products are always on hand.

If your customers also tend to order certain items at the same time, keep them close together to reduce picking times. For instance, someone ordering a new comforter may also order new pillows. Keep like-minded items in adjacent industrial storage bins to speed up fulfillment time.

Organize and Label Your Storage Containers

Nothing will impede your throughput like poorly organized inventory. Your pickers need to be able to find what they need in a matter of seconds without second-guessing themselves. Make sure all your goods are in clearly labeled, easily accessible containers, such as space-saving industrial storage bins and other bulk containers.

Stackable crates and bins help you conserve storage space around your warehouse so your employees won’t have to travel as far to retrieve the products they need. Use stack racks to keep your containers off the ground. Assign certain types of products to different shelves so your employees always know where to look for these items.

Plastic organizer bins make it easy to retrieve loose items. They have a slanted opening so your pickers can grab what they need without having to open the container or reattach the lid.

Organize your warehouse with industrial storage bins and other types of containers to accelerate the product retrieval process.

Routinely Audit and Improve the Layout of Your Space

The layout of your warehouse should always be changing for the better. Use data analytics to analyze the layout of your facility and look for ways to speed up the order fulfillment process. You have so many options when it comes to organizing your containers, moving stack racks and even the labeling and numbering of your products.

Regularly consult this data to make sure you’re running your warehouse as efficiently as possible. Processes are bound to change as some products become more popular and others fall away with your consumers. Keep in-demand products near the front and continuously reorganize your facility based on what’s working and what’s not.

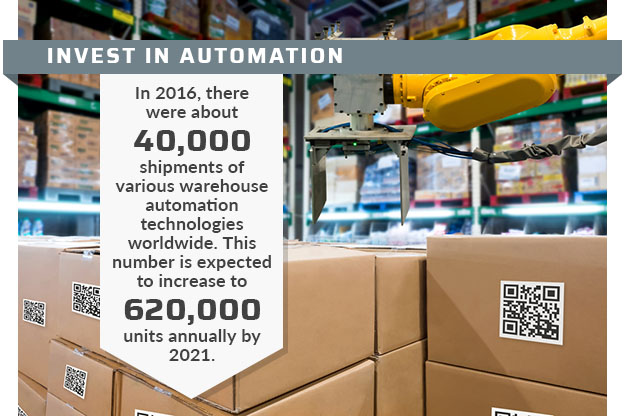

Invest in Automation

Nothing will boost your throughput like warehouse automation. From order processing to packaging and product retrieval, AI can help you transform your facility into a well-oiled machine. Automatic pickers use the same pathways to gather products for a new shipment, reducing hesitation and variables in the product retrieval process. You can easily reprogram these stockers to experiment with new pathways as you look for the fastest route to order fulfillment. Pressure-sensitive scanners help you retrieve items and packages safely without damaging the contents. You can also use AI-powered machines to quickly package your products and prepare them for shipment.

Connect your CRM or sales platform to your AI warehouse equipment so every order will automatically fulfill itself. All you have to do is watch and monitor the process for quality assurance. These machines can also work 24/7 without stopping and they can get moving in just a few seconds, helping you simplify and quantify every aspect of the retrieval process.

Supply chain and warehouse managers understand the value of automation and are investing in this equipment in greater numbers. In 2016, there were about 40,000 shipments of various warehouse automation technologies worldwide. This number is expected to increase to at least 620,000 units annually by 2021.

Integrate Your WMS

If you use a warehouse management system (WMS), integrate it with the rest of the supply chain, including product and delivery tracking systems, your CRM or sales platform and your supplier management software. This reduces inefficiency in the workplace by syncing the entire supply chain. You don’t have to worry about certain data points getting lost in the shuffle or reentering important information into another database.

As soon as an order comes in, your WMS will initiate the product retrieval and order fulfillment process. If a package or an order from one of your suppliers will arrive later than expected, you can automatically adjust your processes accordingly. You can also make sure all your packages are ready for shipment when the truck arrives so you don’t miss important deadlines.

Incorporate all relevant data into your WMS for a completely integrated supply chain.

Analyze Customer Buying Habits

Instead of waiting for your customers or clients to order more products, you can be more proactive with your approach to warehouse management with data analytics. Mine the data you’ve collected on your customers to anticipate their buying habits. From seasonal demand to future repeat purchases, you can quickly figure out which products your customers will likely order in the future. Use this data to get your warehouse ready for these future orders so you can get them out the door as fast as possible. You can anticipate peak demand on a daily, weekly, monthly and yearly basis so you’re never scrambling to fulfill more orders.

You can also use this data to reorganize the layout of your facility. Some of your customers may have a habit of ordering one kind of product with another. Use this data to group similar items on the shelf to reduce fulfillment times.

Differentiate the Space to Avoid Overcrowding

On a simple level, avoid overcrowding your storage space and inventory. Seeing too many similar items on the shelf can easily overwhelm even the most competent warehouse employees. Do your employees a favor and break up the space so they can quickly make sense of the items in front of them.

If you have several containers with smaller items, space them out so your employees have a place to rest their eyes. Stuffing too many barcodes, signs and product categories in a tight space will ruin your product retrieval times. Create a layout that makes sense to you and your team so your employees can quickly find what they need without pulling their hair out.

Collect Feedback from Your Employees

As a warehouse or supply chain manager, it’s important to remember that your employees may have plenty of ideas in terms of how to best organize your facility. They’re the ones retrieving products and fulfilling orders so you should always leave room to listen to what they have to say. Talk to your staff about improving the layout of your facility and listen to their suggestions.

Your employees are always taking notes on the job whether they realize it or not. From in-aisle traffic to SKU confusion, your employees have probably seen it all. Learn more about what’s missing from your layout and try to incorporate these changes into your new strategy. This also helps your employees feel more valued on the job, instead of blindly taking orders from their manager or supervisor.

But What About Manufacturing?

Up until this point, we’ve mainly discussed throughput from a warehousing perspective. But you can also improve your throughput during the manufacturing stage.

Just like with your warehouse, start by analyzing the manufacturing process and look for bottlenecks that could be slowing you down. Find ways around these bottlenecks by introducing new equipment, changing the layout of your facility or simplifying routine processes. Audit the workplace for possible hazards that could slow down production or injure your employees.

Once you’ve identified some of the issues slowing down the manufacturing process, work with your employees to find a solution. Talk to them about how the process can be improved, what aspects seem to take the most time and how you can speed things up without sacrificing the quality of your products.

Boosting throughput all starts with effective employee training. If you make changes to the manufacturing process, educate your employees on these changes and why they’re important. Get everyone on the same page to ensure this new approach is a big success.

Just like the warehouse, you may decide that automation is the best route for your manufacturing facility. Get rid of routine processes and replace them with machines that can get the job done in a fraction of the time.

Wrapping Up

In today’s ultra-competitive eCommerce market, boosting throughput has become the name of the game. You need to successfully deliver and manufacture as many quality products to your customers as possible with impeccable customer service if you want to get ahead in this industry. New technology like artificial intelligence and data analytics are changing the industry’s approach to warehouse management. It’s all about having access to the right information. Keep up with the latest trends to stay competitive and invest in the right storage and warehouse equipment.