Thinking of starting a warehouse business? With the eCommerce and warehousing industries booming, now’s a great time to invest in a storage facility. You can work with other companies as you store, sort and distribute products throughout the supply chain.

Thinking of starting a warehouse business? With the eCommerce and warehousing industries booming, now’s a great time to invest in a storage facility. You can work with other companies as you store, sort and distribute products throughout the supply chain.

But starting a warehouse business is easier said than done. There are lots of different ways to go about setting up and managing a warehouse space. Learn the ins and outs of starting a warehouse business, including finding and leasing a space, investing in the right storage and inventory management equipment and hiring and training your employees.

ABOUT THE WAREHOUSE INDUSTRY

According to the Bureau of Labor Statistics, the warehousing and storage industry is a subcategory within the transportation and warehousing sector. This industry is responsible for the warehousing and storage of general merchandise, refrigerated products and other warehouse products.

Typically, these facilities are not designed to sell these products, but rather storing them and keeping them secure until they must be moved to a new location. Some warehouse facilities and businesses are also responsible for logistics services, including the transportation or distribution of these products.

Logistics services can include:

- Labeling

- Breaking bulk

- Inventory control and management

- Light assembly

- Order entry and fulfillment

- Packaging

- Pick and pack services

- Price marking and ticketing

- Transportation arrangement and management

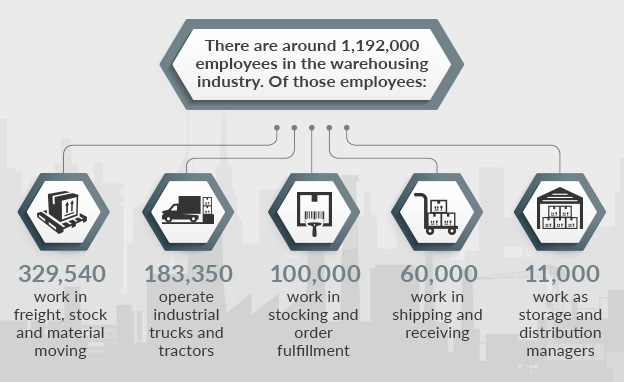

Within the warehousing industry, there are around 1,192,000 active employees. Of those employees: 329,540 work in freight, stock and material moving; 183,350 operate industrial trucks and tractors; just under 100,000 work in stocking and order fulfillment; just under 60,000 work in shipping and receiving; and just over 11,000 work as transportation, storage and distribution managers.

In the age of eCommerce, the warehouse industry is booming. Today, the average size of a warehouse is more than 180,000 square feet, compared to 127,000 square feet from 2000 to 2006. The average number of SKUs handled by the average warehouse continues to rise year after year as more consumers choose to order their products online instead of visiting a local brick-and-mortar store. This means warehousing and logistics companies are now tasked with moving products to a local distribution center or directly to consumers, instead of dropping them off at a store.

STARTING A WAREHOUSE BUSINESS

Getting your warehouse business off the ground is similar to other small business ventures, albeit a few differences. Keep these considerations in mind as you go about building your warehouse business.

Researching the Competition

Like any new business venture, you need to research your eventual competitors, so you can carve out your own path to success. Warehousing companies can cater to many different kinds of clients and industries, including everything from temperature-sensitive food and medicine to consumer electronics and industrial goods.

Research your competitors to learn more about what kinds of products your competitors store at their facilities and what kinds of services they offer. Use your findings to differentiate your new business model from that of your competitors. If these companies limit themselves to certain types of products and industries, consider focusing on securing clients in other industries. If these companies limit their services to warehousing and storage, consider adding product assembly, packaging and other logistics and transportation services to your business.

If possible, visit these facilities in-person to learn more about how they organize and manage their warehouse. If you don’t want to reach out to competitors in your area, consider visiting warehousing facilities in the next town over. You’ll quickly learn about the ins and outs of inventory management, as well as some of the biggest challenges facing the warehousing industry and how to solve them.

Choosing What Kinds of Customers to Serve

Now that you’ve researched the competition, it’s time to choose what type of customers you want to serve and what kinds of products you want to store at your facility. Carving out a specific niche for your warehouse will help you better anticipate the needs of your business. Choosing your warehouse space all comes down to what kinds of products you need to store. You’ll need more space if you want to store large industrial products, bulk items and other large containers. But you may not need as much space if you’re looking to store smaller consumer goods.

Find businesses and clients who need or carry these products and figure out how to incorporate your new business into the local supply chain. Determine how long you might need to store these kinds of products, what kind of turnover you can expect and whether you need to store or handle these items in a particular way.

These decisions will help you invest in the right kind of warehouse facility, so you don’t end up paying for features or storage space that you don’t need.

Come Up with a Budget

It’s also important to have a firm idea of your finances as you establish this new business venture. Calculate how much income you expect to receive during the first six months to a year. Come up with a plan for securing and retaining new clients to increase your bottom line. As a new business, you won’t have the same reputation and credibility as some of your competitors, so you may need to offer discounts and special services to get the attention of new clients.

Compare your expected income with your overall startup costs, including the cost to rent your storage facility, inventory equipment and storage supplies like stack racks, inventory tracking software and even automation. You should also include your hiring and training expenses into your overall budget, as well as your electricity and utility fees.

It may take several months or even several years before your new business turns a profit, so make sure you have enough capital to sustain your business until it becomes profitable.

Choosing a Warehouse Space

Consider the future of your warehouse business before choosing a space. If you plan on scaling up your operations down the line, give yourself some extra space to work with. If you plan on breaking into new markets and serving clients in new industries, make sure you have the resources to handle these kinds of goods down the line.

Consider how much it will cost to light, heat or cool your warehouse and be on the lookout for drafts, poor insulation and other factors that may increase your long-term costs. Make sure your suppliers have access to your warehouse, so you can get products in and out the door as quickly as possible.

Before choosing your warehouse facility, you also need to make sure you have access to local talent. Warehousing space tends to be cheaper in rural areas, but it may be difficult for your employees to commute to work. Consider securing a warehouse space that’s close to major highways and public transportation to increase your chances of recruiting top talent.

SETTING UP YOUR WAREHOUSE

Once you’ve chosen your new warehouse space, it’s time to get organized and bring your facility to life. Use these tips to start setting up your new warehouse.

Investing in Warehousing Equipment

As you go about moving into your new warehouse facility, consider what kinds of equipment you’ll need to properly store and transport your clients’ products. Every warehouse facility needs some kind of storage and inventory infrastructure, so you and your employees can quickly locate certain products and get them ready for shipment. Set up stack racks to create aisles for these products. You can designate specific shelves and aisles for certain kinds of products to keep your facility organized. This also helps you get some of your inventory off the ground without stacking items on top of each other.

Different kinds of products require certain types of storage containers. Use stackable crates for produce, dry goods, consumer products and other smaller items. Use industrial storage bins for larger consumer and industrial products. Make sure all your items are safe within your storage containers. Your employees should be able to quickly remove the items they need without damaging the rest of the contents of the container. If you’re looking to save money on startup costs, consider buying used storage containers.

Add proper signage and labels to your storage containers and stack racks to help your employees and other warehouse personnel safely navigate your facility. Every aisle, shelf and container should list the name of the contents to minimize product retrieval times. Ensure all aisles, storage areas and other high-traffic areas are properly lit to provide a safe work environment for your employees.

Hiring and Training Your Employees

Once you’ve established a protocol for your warehouse, it’s time to hire and train employees who can help you bring your facility to life. Choose employees who are familiar with the equipment you plan on using in your facility. For example, if you plan on using inventory management software, find candidates who have experience using these programs.

You also need to establish safety procedures for your facility and employees. Make sure all your staff members know how to use this equipment safely without endangering themselves or their colleagues. Post these safety guidelines around your facility.

THINGS TO CONSIDER

To Automate or Not

One of the biggest questions you’ll need to ask yourself as you set up your new warehouse business is whether you want to automate your facility. Automation can be a costly investment for new business owners, but these kinds of devices can reduce labor costs, improve efficiency and help you streamline your warehouse operations. Equipment such as automatic pickers and stockers, package fulfillment and order processing equipment can speed up routine processes so you can get your packages out the door as soon as possible.

Staying Competitive in an Increasingly Competitive Market

With the eCommerce and warehousing industries booming, you need to do everything you can to stand out amid the competition. If you decide to invest in automation, you can use these assets as leverage when negotiating with and reaching out to potential clients. No one wants to work with a warehouse that uses outdated technology. It’s all about making the right impression and winning over clients in your area. If potential clients want to inspect your facility before they agree to give you their business, you’ll need to make the right impression by keeping your warehouse efficient and organized.

Fast, reliable delivery has become the name of the game when it comes to getting ahead in the warehousing business. Automation and a well-organized warehouse space can help you trim your product retrieval and order fulfillment times, so you can better serve your customers. This will only improve your reputation in the industry, helping you win over more clients and increase your bottom line.

IN CONCLUSION

There are lots of different variables and considerations to keep in mind when starting a warehouse. Getting ahead and ensuring your success in this industry all comes down to your ability to serve your customers. Find quality storage equipment and containers, hire qualified, reliable employees and consider investing in automation. Store products safely to avoid sending out damaged items, speed up the order fulfillment process to decrease delivery times and make sure you’re meeting the needs of your customers at every turn.