Industrial equipment suppliers have their work cut out for them. They often have to keep track of hundreds of individual parts and supplies as they manufacture their products in the facility. They also have to find a safe and cost-effective way to transport their merchandise once it’s been built. These products tend to be heavier and much more fragile than consumer goods.

They are also going straight to other businesses, leaving little room for error. Instead of sending the customer a free gift card when their order arrives late, a slight delay in production could spell disaster for these businesses. They may decide to take their business elsewhere if they have trouble getting the equipment and supplies they need to manufacture their goods.

If you work in the industrial equipment supply industry, use these shipping storage containers to improve efficiency and keep your products safe and your customers will always keep coming back for more.

Bulk Plastic Pallet Containers

Nothing says industrial like bulk plastic pallet containers. They are often used to transport large pieces of equipment and other essential components. These containers can be collapsible or not. It all depends on your preferences. Companies often use collapsible pallet containers to clear up additional space around the facility. As soon as the order goes out for delivery, workers can collapse these containers to give themselves more room to spread out. These containers also help condense space on the delivery vehicle. Drivers can stack empty containers in the corner as they make stops along their route.

SHOP COLLAPSIBLE PALLET CONTAINERS

Pallet containers are often made with lightweight plastic, making them the ideal choice when it comes to shipping industrial equipment. You can reduce your shipping costs by choosing a lighter container. The plastic is weatherproof and durable so you don’t have to worry about putting your products at risk during transit.

Wire Baskets

You might associate wire baskets with your local laundromat, but they are actually a fundamental part of the industrial manufacturing process. Companies often use industrial wire baskets to store large items. They usually come with wheels and are kept close to the ground so workers can quickly wheel them around the facility floor.

This is often much easier and less time-consuming than using a lift truck. There is no training required. You don’t have to worry about repairing your equipment. And these baskets are much less expensive than your average lift truck.

Wire baskets also keep inventory visible in the workplace so workers can quickly identify and grab what they need without searching through dozens of different containers on the shelf. Every second counts when it comes to manufacturing goods and retrieving certain parts and tools. If your workers hesitate along the way, they may have trouble getting products out the door on time.

Workers can see through the bars of the basket, helping you stay on top of your inventory at all times. If you run out of a certain item, the empty basket will be a clear reminder that you need to place another order as soon as possible.

Plastic Totes and Trays

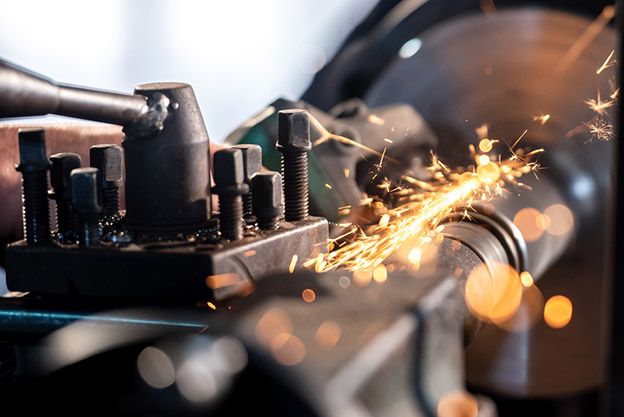

Manufacturing large pieces of industrial equipment isn’t for the faint of heart. Employees often have to use dozens, if not hundreds, of individual parts to manufacture these goods, including loose screws, nuts, bolts, gears, bands and other common ingredients.

Storing all this loose equipment can be a nightmare without plastic totes and trays. These brightly colored containers are perfect for storing smaller items that might otherwise go missing. You can stack them up along the wall, inside a storage cabinet or on your stack racks to quickly organize these materials. Workers can reach for the correct type of screw or bolt without second-guessing themselves. Color code these containers based on their contents to further increase efficiency in the workplace.

We know that the majority of industrial manufacturing firms in the U.S. are quite small. You can also use these containers to make the most of your storage and manufacturing space so your workers have more room to spread out. Invest in the right containers for your business to keep your facility going strong.