Managing a warehouse in the automotive industry comes with its own specific considerations. When you’re assembling complex pieces of machinery that sell for tens of thousands of dollars, you need to make sure that you’re managing your inventory effectively or the results could take a significant bite out of your bottom line. You may end up with spare parts you no longer need, fall behind on crucial delivery timelines or waste valuable time and resources tracking down parts and supplies.

Improving your approach to inventory management will help you get more new vehicles out the door in less time without raising your overhead. Streamlining certain routine processes, adjusting your storage solution and manually spot-checking your inventory will help you avoid potential pitfalls in the production process so you can rise to the top of the automotive industry.

Explore this in-depth guide to improve automotive warehouse efficiency.

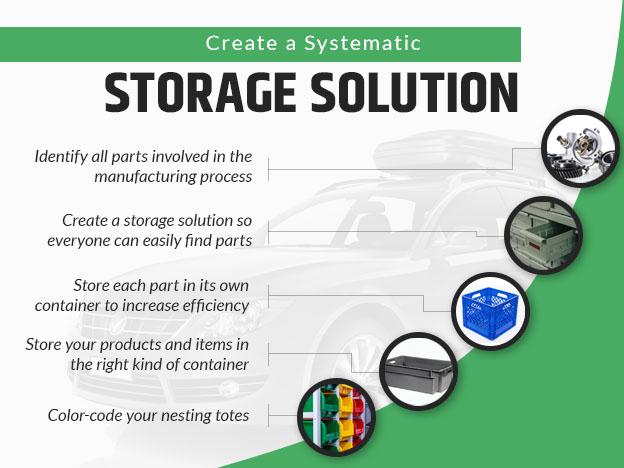

Identify All Parts and Create a Systematic Storage Solution

A single car is typically made up of around 30,000 individual parts. That means you really have your work cut out of you when it comes to managing your inventory. To make sense of everything that’s coming in and out of your warehouse, identify all parts involved in the manufacturing process. Every item should have exact specifications and its own SKU number so you can easily track these items as they move through your supply chain. Marking each individual screw or bolt may seem tedious, but this will help you better monitor your supplies so you don’t fall behind on crucial orders. Label and identify certain tools you and your team use in the warehouse as well, such as wrenches, protective gear and other must-have items.

Once you have this information in the system, it’s time to create a systematic storage solution so everyone in your warehouse can easily find the parts they need. No two automotive warehouses are exactly alike. You need to create a highly customized storage solution for your warehouse based on the size and style of the parts in your inventory.

Store each part in its own container to increase efficiency. Every container should be labeled with the corresponding SKU number as well as information about the item, including its size or a picture to help warehouse employees match the part to the container. Everyone in your warehouse should know where to find specific items. Keep similar looking items several spots away from each other to reduce confusion in the workplace.

Store your products and items in the right kind of container based on their size, shape and style. Many automotive manufacturers will use pallet containers to move and collect items. Plastic nesting totes are perfect for slotting and storing small, dissimilar items, like screws, bolts and nuts. Arrange your containers on the shelf according to need, size and weight. The heaviest items should be kept on the bottom.

You can also color-code your nesting totes to help your employees find what they need in record time. They won’t have to worry as much about bending down to read the fine print on the shelf. Assign colors to each category of item so your employees will always know whether they’re headed in the right direction. This will dramatically improve product retrieval times and help you get orders out the door as fast as possible.

Warehouse tire storage can be a tricky subject for some OEM companies, especially if you have dozens of different tires coming in and out of your facility. Stacking tires on top of pallets is an effective way to move your inventory from point A to point B. You can use a lift truck to quickly move your tires from the loading dock to the storage area.

However, when it comes to long-term tire storage, it’s best to store your tires upright. This reduces the amount of pressure on your tires so they stay as good as new. If you stack your tires on top of one another, they may lose air over time. It is also not feasible to pull a single tire out of the stack when assembling a vehicle. Long-term stacking can also be a hazard. Tall tire towers may fall over if you’re not careful, injuring your employees and inventory in the process. We recommend using stack racks to store tires so you can quickly retrieve the equipment you need. Just pull the tire out of the rack and you can move on to the next stage of production.

Fine-Tuning Your Storage Solution

Your storage system may be a work of art, but nothing is set in stone when it comes to running a warehouse. Work orders and demand for certain products are always changing as OEMs adjust their lineups and introduce new products to the market. As the nature of your business changes, you need to get in the habit of adjusting your storage system accordingly.

As demand fluctuates for certain products, be prepared to adjust the layout of your facility. The most in-demand and commonly used items should be kept in a centralized, easily accessible location to increase efficiency. Your employees should be able to quickly reach for these tools and products without going too far out of their way.

You may also find that your original approach to inventory management isn’t working as well as you were expecting. If you go through all this trouble only to discover you haven’t made much progress in terms of efficiency, continue experimenting until you get it right. Adjust routine processes and the layout of your facility to make things easier on your employees. Talk to your workers about the workflow and listen to their suggestions to make sure they aren’t wasting valuable time on the floor.

Streamline the Sorting and Receiving Process

Now that you have a comprehensive storage solution in place, it’s time to reconsider your approach to inventory sorting and the receiving process. Your employees should follow strict instructions when receiving shipments in the loading dock so you can rest assured everything ends up in the right place.

Keep your bill of materials up to date to improve the receiving process. Some BOMs will change over time as certain parts are removed and others are added. Your employees should refer to the BOM every time they receive a new shipment to make sure it is accurate. They can then address certain inconsistencies in real-time instead of waiting until the driver has already left the facility.

To speed up the receiving and sorting process, use slotting racks and conveyor belts to quickly move your latest inventory to the storage area. Assign individual racks and belts to different categories of products so they make their way to the correct area of your facility. Other employees can then quickly grab the packages and products they need and put them on the shelf without second-guessing themselves.

When enforcing strict guidelines for your workers, it’s best to not overcomplicate the receiving and sorting process. Keep things simple to improve efficiency in the workplace. Your employees should only have to follow a few steps before sending the package off to another area of your facility. Reduce unnecessary steps to keep things moving.

Counter Automation with Manual Spot Checking

Many OEM manufacturers will use warehouse management software to regulate and monitor their inventory and products as they move through the supply chain. Yet, technology is not always foolproof. Errors can easily spring up from time to time so it’s best to manually spot-check your inventory as time goes on. You may have ordered enough inventory according to the system, but there aren’t enough items on the shelf to get your products out the door.

Your employees should get in the habit of double-checking the information in the system to make sure it matches what’s happening on the ground. Use manual spot checks to make sure all your inventory is accounted for. If you see any discrepancies, log the issue in the system and do your best to figure out what went wrong so you can prevent future disruptions.

Regularly Monitor and Adjust Turnover Rates

You may be using automatic reorders to keep your facility well-stocked, but certain automatic tools may end up doing more harm than good when it comes to inventory management. Automatic reorders can leave you with too much of one product and not enough of another, especially if the inner workings of your vehicles are bound to change on a dime.

Before the system automatically sends out another order, take a few minutes to make sure you are ordering products and items you actually need. Keep in touch with the heads of your company to make sure your products haven’t changed substantially.

New fuel efficiency standards and changing consumer habits are pushing the automotive industry in new directions. These changes may throw you for a loop if you are not in the habit of double-checking your inventory management system.

Limit Access to Essential Personnel

Cars are valuable pieces of equipment. Some parts can easily go for thousands of dollars, especially if they are in high demand or are considered rare. With so much money coming in and out of your facility, it’s best to enforce strict security measures to keep your inventory safe. Limit access to your facility to essential personnel only. Talk to your employees about these new protocols and how they should be enforced.

Consider limiting the exits and entrances to your facility. Install security cameras and alarms around your warehouse to keep an eye out for unwanted intruders. You can also station someone at your facility overnight to give yourself some added peace of mind.

When accepting new orders from delivery drivers or meeting with personnel who do not work at your facility, ask for identification to make sure they belong at your facility. Thoroughly vet new staff members to weed out any suspicious characters. Your employees should have a strong history of safeguarding and organizing valuable products.

To increase security, consider switching your system over to blockchain. Blockchain is quickly changing the automotive industry’s approach to the supply chain. Individual carriers and business partners must be verified and approved before handing off valuable supplies and products to the next phase of the supply chain. Automotive makers can utilize blockchain strategies in the warehouse to reduce their chances of fraud.

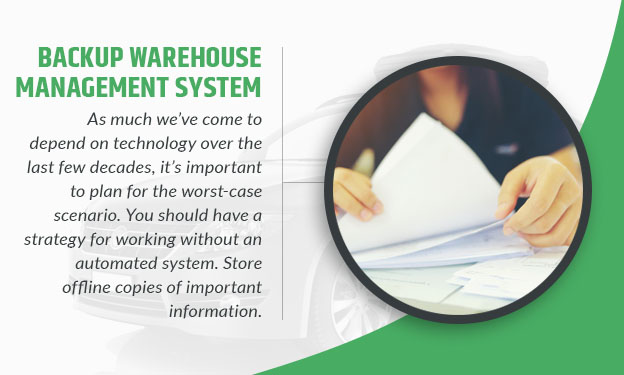

Backup Your Warehouse Management System

As much we’ve come to depend on technology over the last few decades, it’s always important to plan for the worst-case scenario. There’s always a chance your warehouse or inventory management could fail at a moment’s notice, bringing your facility to an abrupt halt. Come up with a backup plan with your team to avoid any potential delays in production. You should have a strategy for working without an automated system. Store offline copies of bills of materials, work orders, inventory lists and other important information.

You and your team may have to go back to using pens and clipboards, but at least you will have everything you need to get vehicles out the door even though you don’t have access to technology. Individual dealerships and customers still need your products even if you’re experiencing technical difficulties. Train your staff on these backup protocols to keep things moving in the right direction.

Running an automotive warehouse comes with its fair share of ups and downs. Use these storage solutions for automotive OEM suppliers to increase efficiency and improve your bottom line. You can closely monitor your inventory at every turn to make sure everything ends up in the right location. No more missing parts and half-finished vehicles. Your customers will thank you for being on time, and you won’t have to worry about losing track of valuable items. Take your warehouse to the next level with these inventory control tips.