Every warehouse is different, but the challenges are often the same. Companies in the automotive industry are increasingly looking for ways to speed up the manufacturing process and reduce costs. Most facilities are made up of hundreds of thousands of moving parts and keeping everything straight can be a challenge for players large and small.

There’s more than one way to run a highly efficient automotive warehouse, but certain layouts work better than others. Use these tips to design the ideal warehouse layout:

Mapping Out the Lay of the Land

Whether you’re starting a new layout from scratch or modifying your existing facility, it’s always best to map out the terrain using a warehouse management software program or old-fashioned pencil and paper. This gives you a chance to adjust different elements of your workspace and test out various scenarios before transforming the space.

Take accurate measurements of the warehouse, including your storage and manufacturing equipment. Experiment with various arrangements to see how they would affect your workflow.

It’s best to keep the product moving toward the loading dock throughout the manufacturing process. Commonly used items, such as nuts, bolts and screws, as well as your most popular goods, should be placed near the loading dock or package-fulfillment center to reduce picking times.

Consider the best width for walking and picking paths to give your employees plenty of room to move around. Toyota has provided a guide to calculating dimensions when using a forklift.

First, you’ll need to measure what’s known as the basic right-angle stacking width, which is the smallest amount of space the forklift needs to be able to turn and enter a pallet. It doesn’t include the length of the pallet or leave any additional clearance. Check your forklift manual or spec sheet for this information.

Next, measure the length of the load from the front of the pallet to the back.

Finally, add a minimum of 12 inches of clearance to give your workers enough space to get in and out.

The equation works out as follows:

Basic Right-Angle Stacking Width + Length of Load + 12 inches = Minimum Aisle Width

This represents the bare minimum. Consider how many lift trucks will be coming in and out of the space at the same time and how much room for error your workers will need. Use the same equation when using automated pickers and stockers, so these machines can move fluidly throughout the space.

Storage capacity is usually limited to 22 of 27 percent of your total warehouse space, but this varies widely from facility to facility. Keep in mind, you will technically run out of space when you hit 85 percent capacity, or you’ll risk endangering employee safety. A warehouse design program will help you calculate your capacity so you don’t go past this threshold.

Utilize vertical storage to make the most of your existing space. Stack racks are perfect for moving your inventory off the ground. Be sure to keep the heaviest and most popular items toward the bottom row or at chest height. Make it easy for your employees to grab items off the shelf, either by hand or using a forklift.

Automotive Warehouse Layout Examples:

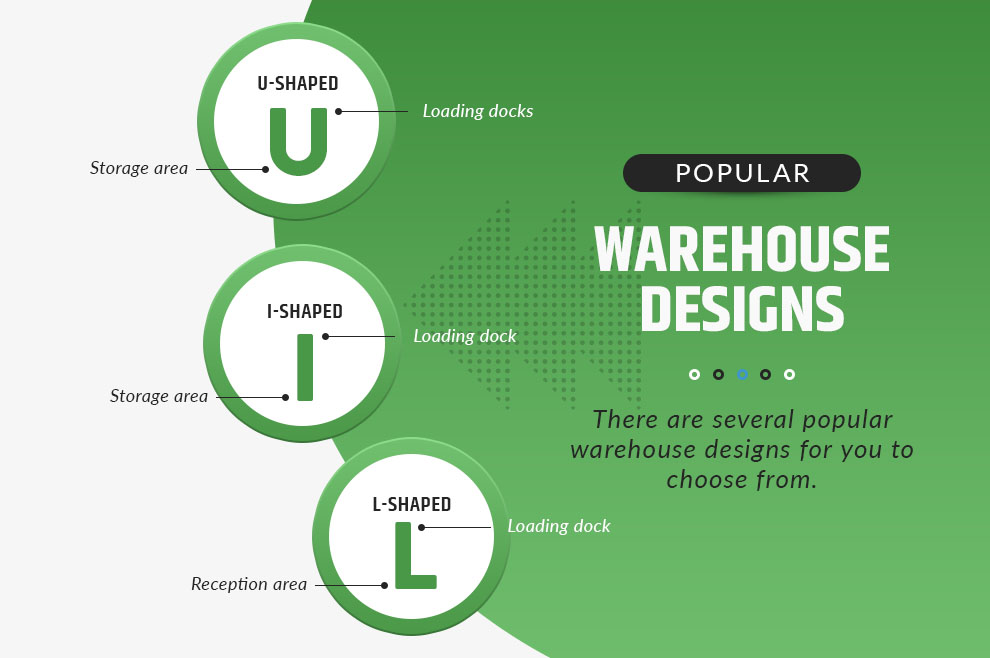

There are several popular warehouse designs for you to choose from. Each comes with specific pros and cons that may work to your advantage.

U-Shaped Design: The space is shaped like the letter “U” with the lower part representing the storage area and each point symbolizing the loading dock and staging/reception area. This keeps workers in both the loading dock and stage area close to the inventory, so they don’t have to travel far to grab products off the shelf. It’s also important to space out the loading dock and reception area so these workers aren’t working on top of each other.

I-Shaped Design: The I-shaped design is better suited to high-traffic warehouses, such as fulfillment centers and wholesalers. The loading dock is located on one end of the facility with the staging area on the opposite side and the storage area in between. Products slowly make their way from the reception area to the storage area and, finally, to the loading dock, all while following a straight line. This layout can help increase efficiency when it comes to fulfilling orders and moving merchandise.

L-Shaped Design: This layout creates a 90-degree angle. The loading dock is at one end with the reception area around the corner. The storage area sits near both access points for fast order fulfillment and product sorting.

Streamline Product Picking with Industrial Wire Baskets

Choosing the Right Storage Equipment

Once you have an idea of what you want to do with the space, it’s time to start considering how you plan for storing individual items on the shelf. Automotive warehouses are typically made up of hundreds of thousands of parts and supplies. Your storage system should make it easy for your employees to find what they need without going too far out of their way.

Use the following storage containers to speed up picking times without putting your inventory at risk:

Pallet Container: Every warehouse revolves around the humble pallet container. These containers are designed to fit onto a pallet for fast, hassle-free loading/unloading. Find pallet containers that match the exact size and dimensions of your existing pallets for a perfect fit every time. If the container is too large for the pallet, the load may be unstable.

Use bulk pallet containers to further increase efficiency. These containers can safely hold up to 1,500 pounds. Your team will be able to move large quantities of goods using a forklift or lift truck. This will help save time when loading/unloading vehicles and sending out your goods for delivery.

Wire Baskets: Nothing keeps your inventory visible like industrial wire baskets. They are best used to store large items that won’t fall through the cracks, such as tires, wheels, upholstery and components of the interior. Store these items in industrial wire baskets so your team doesn’t have to open the container to see what’s inside. Workers will be able to recognize the contents in a matter of seconds, so they can find what they need and return to the loading dock or manufacturing process as fast as possible.

Many containers also come with wheels, which makes it easy to move inventory from one side of the facility to another. Your workers won’t need a lift truck or pallet jack, helping them stay on task.

Metal Bins: Metal bins are considered the backbone of the automotive industry. So many parts and supplies tend to be made of metal. That’s why it’s important to use a metal storage container. These bins typically come with an open slat or drop-down opening at the top, making it easy for your employees to reach inside the container. They will be able to see what’s inside as they approach the container, without having to open a lid.

Metal bins are perfect for storing many items used to manufacture cars and car parts, such as screws, cords, metal frames, bolts, caps, lights and other automobile accessories. It’s always best to match the material with the storage container. If you store metal items in a plastic container, sharp points could scratch up the surface, leaving the container unusable. Use metal bins to keep your storage equipment safe on the shelf.

Additional Storage Considerations

Choosing a container is only the start of the process. Once you acquire the right storage containers for your automotive warehouse, it’s time to start loading your products onto the shelf. However, there are several things you can do to make it easier on your employees.

Color-Coded Containers: Regardless of what kind of container you choose, consider assigning specific color schemes to certain parts and materials. Most of the containers mentioned above come in a range of different colors. Use these designs to your advantage, so your workers can easily spot specific items without having to look inside the container.

You can arrange your inventory by size, popularity, make, model or whatever makes the most sense to your employees. Primary colors, such as red, blue and yellow, can denote specific categories. This adds another layer of logic to your system, so your employees don’t have to second-guess themselves in the middle of the aisle.

Signage and Visibility: Your workers should have everything they need to find items on the shelf without asking for help. Use clearly marked signs to steer your workers in the right direction. Come up with clear categories for your inventory, so everyone interprets these signs in the same way.

Visibility is also key to improving efficiency. Give your workers plenty of light to navigate the space. They should be able to see everything going on around the container. This will help them inspect storage conditions and potential safety hazards before they turn into major headaches down the line.

Consult with Your Employees: It may be tempting to make all these decisions in a vacuum, but nobody knows your warehouse like your employees. They are the ones moving inventory and picking products off the shelf, so develop a plan in conjunction with your employees. This will give them more authority over their work environment, which can increase job satisfaction and reduce turnover rates.

At the end of the day, it’s all about helping your employees work smart and not harder.

Test Out Your Plan: A plan isn’t set in stone. Once you have an idea of how you want to design the space, it’s time to put your plan into action. Rearranging the space in full may take several weeks, so be sure to conduct a timed trial before committing to the new plan.

Start by bringing at least one aspect of your layout to life. Your employees should then go about their business fulfilling orders or sorting inventory using the new layout. Keep track of key performance indicators (KPIs) to make sure the layout is working to your advantage.

If your workers are using scanners and barcodes, the automated warehouse system will time certain tasks in the system. Review these performance statistics before committing to your new layout in full.

Learn About the Automated Warehouse System in Our Guide

Implement the Internet of Things (IoT): Automated warehouse systems are here to make your job easier. The program will automatically log KPIs in the system as your workers adjust to the new layout. This will help you keep tabs on their progress over time. If these statistics aren’t where you’d like them to be, consider making additional changes to the layout until you reach peak efficiency.

The average automated warehouse system comes with dozens of features that will help your employees stay on task. Voice and visual commands will steer your employees in the right direction as they navigate the rows of inventory. Product tagging shows you where items are in real-time.

If something goes missing, your workers can look up the specific SKU number in the system, and the GPS will show the item’s location on a map of your warehouse. Your team won’t have to waste time looking for missing items. Workers can also use the GPS to quickly locate items on the map so they don’t get lost along the way.

Ideally, your workers will scan items every time they move them from point A to B, so the tracking system stays up to date. You can review virtually every aspect of your warehouse using the automated system, so you always have the information you’re looking for.

Following the Guide Will Lead to the Best Decisions

There’s more than one right way to design an automotive warehouse, but these tips should set you up for success. Small changes can help you increase efficiency and reduce downtime. Every warehouse is a work in progress. Refer to this guide as you continue making changes to the space so every decision works in your favor.

Image Credits

Andrei Kholmov/Shutterstock.com

Dmitry Kalinovsky/Shutterstock.com

Syda Productions/Shutterstock.com

Charoenpong R/Shutterstock.com

Unique Vision/Shutterstock.com