The U.S. steel industry is going strong. According to the International Trade Commission, total U.S. steel production in 2018 increased to 86.6 million metric tons from 81.6 million metric tons in 2017–an 11.4 percent increase. However, studies show trade tariffs and other geopolitical factors have put the steel industry on edge. Demand tends to fluctuate on a dime as customers take their business to different manufacturers all over the globe. It’s all about getting the highest-quality steel at the most affordable price.

If you’re in the steel industry, you need to focus on getting your products out the door as quickly as possible without raising costs. With warehouse rates on the rise, you need more with less space. That means organizing your inventory to a tee so you’re not hanging onto merchandise that’s no longer profitable for your business.

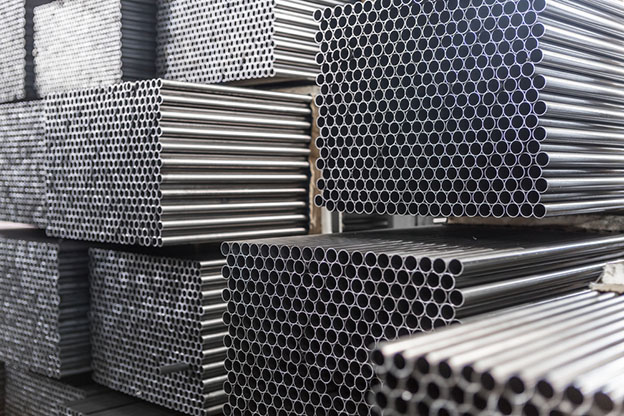

The steel business isn’t the same as other industries. Steel parts tend to be extremely bulky and cumbersome. Without the right equipment, your employees could easily injure themselves when trying to shimmy products to the loading dock. Steel also tends to absorb the temperature of your facility. Workers may need to use gloves when handling certain products in case they are too hot or too cold to the touch. Steel is also notoriously sharp, so you’ll need to protect your workers from rough edges and surfaces.

Regardless of your inventory, use these steel manufacturing and storage tips to improve your operations.

Getting Products Off the Ground

It’s never a good idea to store pieces of steel on the ground. Picking pieces of steel off the ground can be a challenge. Your workers will have trouble getting the forklift under the steel. It may take you that much longer to prepare your products for shipment and delivery. Steel parts will also absorb the temperature of the floor, which can lead to rapid temperature fluctuations.

Instead, store steel plates and parts on a series of stack racks to get your inventory off the ground. You can slide your products onto the shelf vertically or horizontally, depending on the size and shape of your goods. Your employees can easily slide the forklift in between individual slats of steel, helping them retrieve the products they need as quickly as possible. You won’t have to worry about your workers pricking themselves on pieces of steel as they try to move inventory off the ground and over to the loading dock.

Sorting Products into Different Containers

If your facility manufactures steel in a variety of sizes and styles, you’ll need to sort your products accordingly. Putting dissimilar items in the same container can delay the order fulfillment process. Staff members may have trouble finding specific sizes and types of steel throughout your facility. With all those sharp edges, you don’t want your workers rummaging through large bins and containers.

Use different containers to properly sort and store inventory on the shelf so your employees can quickly find what they need. It’s best to use metal storage bins when sorting and storing steel products. Steel can easily cut or damage plastic totes and containers, so go with collapsible metal containers instead. With openings and slats, your team members can quickly reach in and grab certain items without dealing with lids and other variables during the retrieval process.

Use Metal Pallets for Safe, Efficient Handling

It’s also best to use metal pallets when lifting or transporting steel items. Wooden pallets can spread dirt and debris throughout your facility, increasing the chances of slips and falls. Plastic pallets may get damaged during the handling process, so choose metal for more peace of mind.

Use forklifts to quickly and safely move bulky pieces of steel so your workers don’t injure themselves in the process. Avoid throwing or dropping your metal pallets to cut down on noise pollution.

Audit and Alter Your Operations to Increase Efficiency

There’s more than one way to store and handle various steel components. You may decide storing slats horizontally is the best choice for your business, but you won’t know the difference until you collect data on your operations. Use smart scanners and inventory tracking software to monitor routine processes. Experiment with different layouts and storage systems and compare the results to find the best solution for your business.

The steel industry comes with its fair share of challenges and obstacles, but you can overcome them and improve your operations with the right storage equipment.