The food and beverage industry moves at its own pace. Unlike traditional consumer goods, food and beverage products come with an expiration date. These products need to reach consumers as quickly as possible, or they may end up in the trash. Depending on the nature of your goods, you may need to keep them a certain temperature during transit. Even if your goods aren’t frozen or refrigerated, room-temperature items can easily spoil if there’s too much heat or humidity in the air.

The food and beverage industry moves at its own pace. Unlike traditional consumer goods, food and beverage products come with an expiration date. These products need to reach consumers as quickly as possible, or they may end up in the trash. Depending on the nature of your goods, you may need to keep them a certain temperature during transit. Even if your goods aren’t frozen or refrigerated, room-temperature items can easily spoil if there’s too much heat or humidity in the air.

In addition to the challenges of running a warehouse, you’re responsible for the health and safety of your customers. One mistake could easily disrupt your business or put your customers at risk. But with the right tools and insights, you can monitor your products in real time to make sure they arrive at their destination on time and at the right temperature. Use these warehouse logistics tips to keep your customers satisfied.

Running a Warehouse in the Food and Beverage Industry

The food and beverage industry represents a significant portion of the U.S. economy. With annual foodservice distribution industry sales at $280 billion in 2017, the foodservice distribution industry operates 153,000 total vehicles, employs 131,000 drivers and impacts more than one-million jobs nationwide.

However, the industry is changing fast. Consumers are choosing to order their products online and have them delivered right to their front door instead of making the trip to their local grocery store. From your perspective, this generally means you’ll need to ship your products to individual consumers or distribution centers instead of delivering large quantities to a retailer. Orders will be more personalized and contain smaller quantities, so you may need to rethink the order fulfillment process if you’re putting items together for individual consumers.

Whether you’re delivering your products to a retailer, restaurant or individual shoppers, you still need to make sure your goods stay at the right temperature. In many cases, customers want their food as quickly as possible, so you need to move your products quickly in order to keep up with demand.

Food and beverage manufacturers and distributors are also dealing with more SKUs than ever before. More brands, including healthier and independent sellers, are getting into the industry and consumers are starting to buy food and beverage products from other countries, which only adds to the confusion.

Consumers are starting to eat healthier than in years past. Shoppers are starting to ditch canned foods, pre-made dinners and powdered meals for fresher options, like meat, fruits and vegetables. This means your business may need to handle more sensitive products instead of boxes of macaroni and cheese.

Track Your Inventory in More Ways Than One

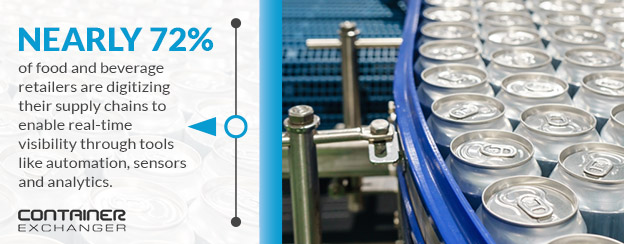

Considering the sensitive nature of your inventory, you can’t afford to take any chances when it comes to the condition of your products. That’s why it’s important to collect as much data as you can on the storage, distribution and shipping processes. In terms of transportation, a slight delay could easily ruin an entire shipment of goods. Improper storage techniques will also ruin your inventory. But new technology is here to simplify the logistics process. Nearly 72 percent of food and beverage retailers are digitizing their supply chains to enable real-time visibility through tools like automation, sensors and analytics.

You can use real-time GPS trackers to monitor the location of your products as they move through the supply chain. You will be the first to know if your products are delayed for any reason. You can then share this information with your customers or business partners so they can adjust their operations accordingly. If your products are delayed, your team or business partners can inspect your products once they’ve arrived to make sure they’re still safe to eat.

When it comes to shipping temperature-sensitive products, like produce, meat, frozen and refrigerated goods and pharmaceuticals, you can use remote sensors to monitor the temperature of your goods as they move through the supply chain. Thermostats will automatically log the temperature of your goods in the system so, rest assured, your goods are safe to consume. Share this information with your customers and partners to increase transparency.

Once you start collecting data on your products, you can use predictive analytics to make the most of this information. Use your inventory management system to make predictions about your operations, such the likelihood of your products getting delayed or certain products dropping below a certain temperature. Based on previous incidents, you can be proactive with your distribution efforts to make sure these kinds of mishaps don’t become a habit. There are so many variables at play when it comes to shipping and transportation, so use this data to better prepare for the unexpected.

Coordinate with Your Suppliers

Your suppliers will either make or break your logistics efforts. From small farms to massive manufacturing plants, your suppliers need access to information about your business if they’re going to help you accomplish your goals. Once you start collecting data on your inventory and generating demand estimates, pass this information along to your suppliers to keep them informed. Your business partners have their own concerns to worry about, so give them as much advance notice as possible to make sure you have everything you need to fulfill orders.

Create additional supply chains if some of your suppliers become unreliable. Crop shortages, weather-related incidents and trade tariffs can disrupt your supply lines, so partner with additional companies to decrease the chances of a delay or disruption.

Organizing Your Facility

Nothing will slow down your operations like a disorganized facility. Use stack racks to create aisles throughout your warehouse. Your employees should be able to find what they need on the shelf without running into each other. Use proper lighting and signage to guide your staff members through the facility. Nesting totes and food grade totes keep your products accessible, so pickers can quickly grab what they need.

Keep your most popular products close to the front of your facility so your employees can fill orders as quickly as possible. Popular items should also be low to the ground to simplify the retrieval process. Even though you’re monitoring your inventory in the system, spot check containers to watch out for damage, leaks and miscounted inventory.

Remember that heat rises, so keep temperature-sensitive items low to the ground. Look for sudden changes in temperature around your facility, such as drafts, heaters and poor insulation that may change the temperature of your products unexpectedly.

Choose the Right Containers for Your Products

Nothing could be more important than the containers that carry your products to their destination. The wrong storage container can easily ruin your products. Some items may get damaged or bruised along the way, such as fresh produce and baked goods. If your containers aren’t sealed properly, germs and other bacteria may slip inside, contaminating your goods.

Some containers can also leave your products vulnerable to temperature changes. Heavy or overly cumbersome containers will also slow down your operations. Your staff may take longer to load and unload your containers, which can lead to spoilage and missed deadlines.

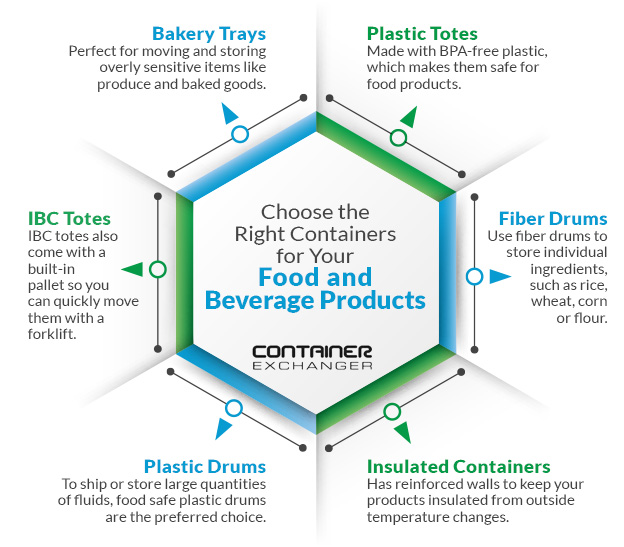

- Bakery Trays

You have several options when it comes to storing and transporting your inventory. Food grade totes and bakery trays are perfect for moving and storing overly sensitive items like produce and baked goods. Use bakery trays to transport baked goods so you don’t have to worry about your products sticking to each other getting damaged during transit. Separate trays keep your items isolated. That way, they don’t get crushed inside the container. With vented sidewalls, air can still pass through the container, enabling your baked goods to cool off.

- Plastic Totes

Food grade totes make shipping and storage easier. These containers are lightweight and reusable, so you can keep your storage costs as low as possible. Totes stack on top of each other, so your team can quickly move several containers at once. Just secure them to a dolly or forklift and you can load up a delivery vehicle in just a few minutes. You can also stack unused totes in the corner to make the most of your warehouse space.

Look for food grade plastic stacking totes. They’re made with BPA-free plastic, which makes them safe for food products. When it comes to storing your inventory, keep the container flaps open so your employees can see what’s inside. This makes sorting much easier. Your employees can quickly stash products in the bin without worrying about lids or putting items in the wrong containers.

- IBC Totes

IBC totes have become a staple of the beverage industry. They can usually hold up to 330 or 275 gallons of fluid, such as drinking water, oil and other food and beverage items. You can move large quantities of goods in less time, helping you meet important deadlines. The container is encased in a metal cage to help secure your products. You don’t have to worry about damaging the container or springing a leak during transit. IBC totes also come with a built-in pallet so you can quickly move them with a forklift. Use the attached nozzle to quickly deploy your products.

- Fiber Drums

Use fiber drums to ship and store large quantities of dry goods. You can use fiber drums to store individual ingredients, such as rice, wheat, corn or flour. They’re made with lightweight fiber materials, so you and your team don’t have to work as hard when loading and unloading cargo. Lightweight materials also help you reduce the cost of shipping. They come with secure lids that keep your products safe during transit.

- Plastic Drums

If you’re looking to ship or store large quantities of fluids, food safe plastic drums are the preferred choice. With 55-gallon containers, you can easily move your products from point A to point B. Keep them on their side to roll them on and off the truck. You can also stack them in your facility to make the most of your space.

- Insulated Containers

Use insulated containers to keep your food items at the right temperature. They come with reinforced walls to keep your products insulated from outside temperature changes. These containers tend to be more expensive than others, so consider buying used insulated containers to cut down on expenses.

Keeping Your Products Safe During Transit

Once you have the right containers, it’s time to secure your products for transit. Pack your containers until they’re full without jamming too many items inside. This way, your products won’t roll around during transit. Use plastic or foam inserts to keep fragile items in place, such as cakes, breads and other unique creations.

When loading your vehicle, keep the heaviest boxes and containers at the bottom of the stack so they don’t damage the items underneath.

IBC totes and drums help you keep your products safe during transit. They come with reinforced lids and openings so you don’t have to worry about springing a leak. Thoroughly inspect your containers to make sure they’re still safe to use.

Your staff should be on the lookout for warning signs something may be wrong with your cargo. Have them look in the back of the truck throughout the day to make sure nothing is leaking or has been tipped over.

Opening the door to a refrigerated truck can easily change the temperature of your products. Talk to your employees about safe handling instructions. Post images and signs near the back door to remind your employees to keep the door closed whenever possible. You can use automatic sensors and alarms to make sure your employees don’t leave the door open.

The food and beverage industry comes with its fair share of challenges, but overcoming these obstacles all starts with having access to the right equipment and technology. Invest in smart sensors, thermometers and packages to keep your goods secure during transit. Stay vigilant throughout the day to keep these items intact. Use these tips to deliver your goods with more peace of mind.